1. Oldindan yuklash o'tkazmasi

Yuqori yuk uchun 3 ta to'g'ri zanjirli qatorlardan iborat. Ko'p og'ir konstruksiya bilan pirof metallda montajlangan. Zanjir, vaq, yengil va motor redukтор bilan ishlaydi. U forklift yordamida to'plamlarning tartibi yo'naltirish uchun tepada qo'llab-quvvatlanadi.

2. Zanjirlik konveyorli yuk oshiruvchi stol

Qatlam paketini suvni qaytarish uskamasiga ta'minlash uchun hidrolik pantograf oshiruvchi. Operator uni pedal orqali boshqaradi va doimiy darajada ta'minlash uchun buyurtma beradi. Qatlam uz garimdagi paytda 2 stol bir vaqtning o'zida ishlaydi. Faqat qisqa garimdagi paytda bitta stol.

Dental pumpa va to'liq hidrolik modul bilan hidrolik orqali ishlatiladi.

3. Suvni qaytarish uskamasiga yuklovchi

Ko‘pirlar bilan tizimdagi sistemalar vaikki yonilgichlar uchun ikki shina bilan qoplangan bosqichli rollar. Bu rollar yonilgichlarni yuvalash uchun qurulma kirgizishga yo'naltiradi. Servo pozitsionirovka qurilmasi, yonilgich uzunligiga va yuvish tezligiga qarab 4 yolni avtomatik ravishda almashtiradi.

4. Vakuum beruvchi

Pisuvchi tizimi yonilgichni oshirib, operatorning talabidan foydalanmasdan yuvish uchun tayyorlaydi.

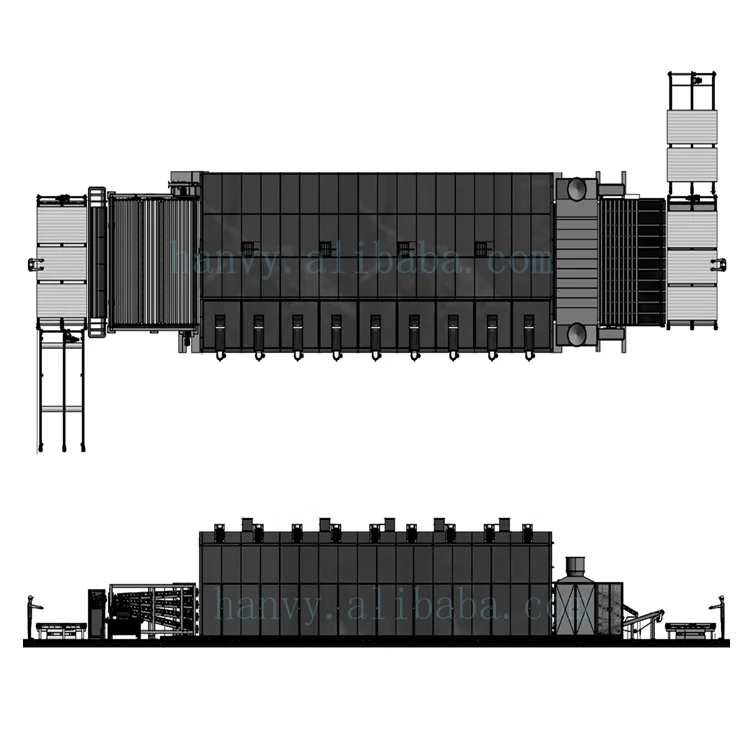

5. Yonilgich Roll Yuvaligi

- Ishlash kengligi: 6m

- Roll uzunligi: 6.2m

- Jami kenglik: 8.6 m

- Balandlik: 5m(asosiy fundament bilan)

- Loader/Unloader bo'lmagan jami uzunlik: 17 m

- Kirish rollarining uzunligi: 4.5m

- Qurutish bo'limlari: 7 x 2 = 14.0 m

- Sochish bo'limi: 2 + 1 = 3 m

- Chiquvchi rollar uzunligi: 3.0m

- Qurutish uchun qatorlarning kalinligi: 1.0 dan 4.0 mm gacha

Qobiliyat:

6.5 m3/sa, 1.5 mm kalit qatorini hisobga olsak, yashil holatdan 6% namlikka – 900 kg/m3 ni tuzatish, jami 90% qurutish ishlatilishi koʻrsatkichi va 170°C da ishlaydigan qurutuvchi. Ushbu miqdor belgilangan vaqtda aniq o'lchangan. Haqiqiy kunlik o'rta miqdor boshqa omillarga qarama-qarshi tenglangan: yo'l to'laqligi, qatorlarni qurutish va temperaturasi, boshlang'ich va oxirgi namlik, ish faoliyati to'xtash vaqtlari, qurutuvchini haftada tozalash, qatorlarning kalinligining birxil bo'lishi va hokazo.

Maksimum issiqlik sarfi: 3, 000, 000 kcal/sa

6. Ikki zona uchun avtomatik temperatur nazorati

Avtomatik moslashtirilgan trik vavtali valvul bilan oldindan yig'ilgan qurilma, nemis Honeywell brendidan, masnavi pomplar, filtrlar, transitlar, sensorlar uchun ishlatiladi va boshqalariga

7. Bo'shatish konveyor

Uzun konveyorli sistem, quruvchanlardan quruq mashinaning 4 qattasidagi qonqoroplarni qabul qilib, ulardan Lift stoliga o'tkazadi. Shuning uchun, qonqoroplar bilan ishlash asholanadi. Sushilgichda yoyilgan havo emasdan foydalaniladi.

8. Lift stoli chain konveyor

Qonqorop paketini sushilgichga ta'minlash uchun hidrolik pantograf lift. Operator pedal orqali buyruqlar beradi va sushilgichni bo'shatishda doimiy darajani saqlaydi. Uzun qonqoroplar uchun 2 stol bir vaqtning o'zida ishlaydi. Qisqa qonqorop uchun faqat bitta stol. Charchaq pompa bilan va to'liq hidrolik modul bilan ishlaydi.

9. Bo'shatchi chain konveyor

Yuqori yuk uchun 3 ta chain chiziqidan iborat. Ko'p tomir profil larsida montajlangan, xususan o'rnatilgan asos. Chain, valvlar, yuqilliklar va motor reduktor bilan ishlaydi. Yuk to'plamlarining forklift bilan tartiblangan joylashtirish uchun tepada qo'llab-quvvatlash mavjud.

Yo'q | Mahsulot | HG134\/5900-6+1 | HG134/5900-8+1 | HG134/5900-10+2 |

1 | Vener to'qchaligi | 1-4 mm | 1-4 mm | 1-4 mm |

2 | Namlik | 90% - 4% | 90% - 4% | 90% - 4% |

3 | Ishlab chiqarish kengligi | 5700mm | 5700mm | 5700mm |

4 | Dastur raqami | 4 | 4 | 4 |

5 | Qurutish quvvati | 6 M3 | 8M3 | 10 M3 |

6 | Bu harakat suv bardak consumption | 4000 кг/с | 6000 кг/с | 8000 кг/с |

7 | Ishtirok bo'limi | 6 | 8 | 10 |

8 | Rolik | Ha | Ha | Ha |

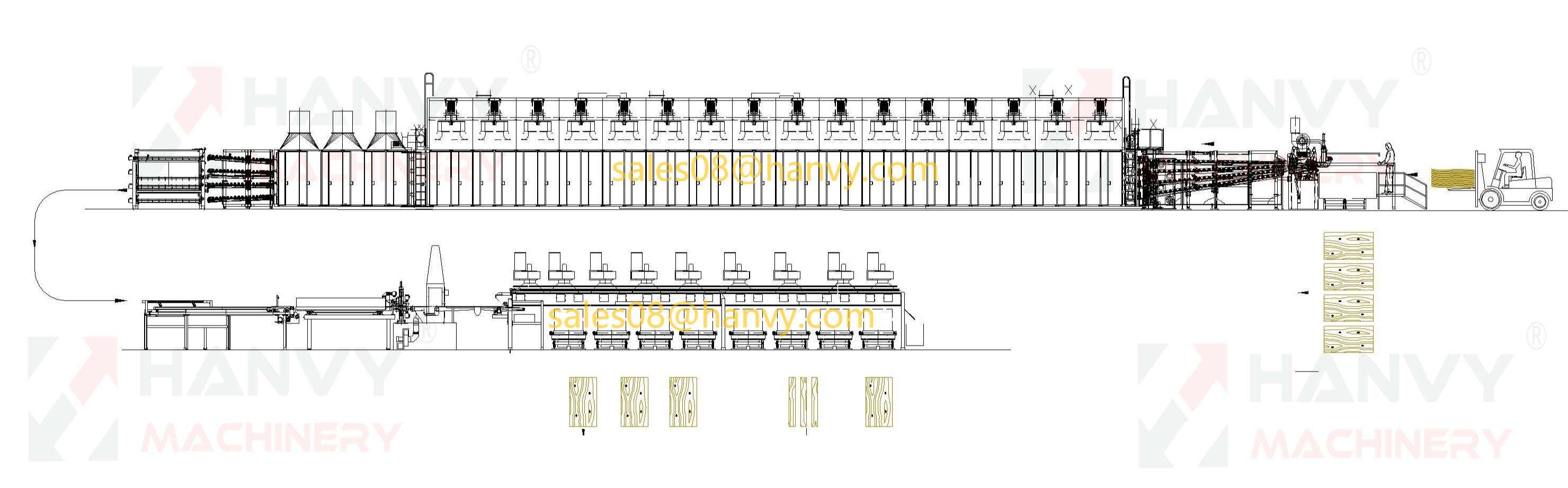

HDR7 avtomatik 4 qattalik 7 bo'limlik rollyuq qatorli quruvchi Hanvy Mashinaning qurilishi, katta miqdordagi rollyuqlarni to'liq va effektiv ravishda quruvchiga aylantirishni xohlaydiganlarga mos keladi. Ushbu innovatsion quruvchi quruvchi jarayonini yaxshilaydi va energiya va vaqtni saqlashga imkon beradi.

4 qatta va har birida 7 bo'lim bor, bu esa rollyuqlarni to'liq quruvchiga aylantirish uchun jami 28 bo'limga ega bo'lishini ta'minlaydi, bunda vaqt shunchaki bir xil. Bu, katta miqdordagi rollyuqlarni quruvchiga aylantirish kerak bo'lgan ishlab chiqaruvchilar uchun maxsusdir, chunki bularning hamma biri katta miqdorda quruvchiga aylantirilishi mumkin juda kam ajratilgan vaqtda. Quruvchi avtomatik taminot tizimi bilan tenglangan, bu esa rollyuqlarni davom etuvchan ravishda taminot qilishga imkon beradi va faoliyatni to'xtatishni oldini oladi.

Rollik usuli orqali ishlaydigan quruvchi to‘garaklar uchun ist sovutishni ta’minlaydi va to‘garaklarning ustida ist oqimi to‘g‘ri ravishda bo‘ladi. Shu jism, boshqa turdagi sovutish usullarida yuzaga kelishi mumkin bo‘lgan to‘garaklarga nisbatan qaydlar yozilmasligini saqlaydi. Bu esa to‘garaklarning yuqori sifatli yuzaiga olib keladi.

Ist va tarmoqni davomiy davom etish orqali sovutish jarayonida aniqlik bilan boshqariladigan elektron boshqaruvi mavjud. Ushbu jismlarning muqaddas texnologiyasi energiya xarajatlari cheksiz ekonomikani ta’minlaydi va sayr etilgan kam, uni karbon urushini kamaytirish uchun qidiruvchi odamlar uchun ekologik yo‘llash hisoblanadi.

Shuningdek, sovutish jarayonida davomiy ist va tarmoqni ta’minlaydigan issiq havo sistemasi ham mavjud. Bu qo‘shimcha sovutish vaqti kamaytirishga, maslahatli darajada efeksiyani oshirishga yordam beradi.

Sovorli va muassir uslubga ega, shuningdek foydali funktsiyalarga ham egadir. U baland sifatli, eng yaxshi daymlik va qarorli materiallardan tayyorlangan. Shuringa qo'shimcha ushlab qoluvchi oson ishlatilishi, oson sozlamalari barcha boshlang'ich foydalanuvchilar va mutaxassislar tomonidan oson ro'yxatdan o'tkazilishi va tushunilishi mumkin.

HDR7 Avtomatik 4 qatorli 7 bo'limli rollyu shixlatuvchi yuqoriga qarashli yuqirinak suvni chiqazish qatori Hanvy Mashinasi tomonidan ishlab chiqilgan ishlab chiqarish vazifalariga qarshilik ko'rsatadigan ishonchli, faoll va ekologik ravishda mustaqil yechimdir. Undagi eng asosiy texnologiya va innovatsion uslubi uni shixlatuvchi ishlab chiqarish jarayonini yaxshilashni xohlaganlari uchun eng yaxshi yechim hisoblanadi va har doim sifatli natija ta'minlaydi.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ