การใช้งานผลิตภัณฑ์

เราเป็นผู้ผลิตเครื่องจักรไม้อัดมืออาชีพที่มีประสบการณ์มากกว่า 30 ปี ในเมืองเว่ยไห่ มณฑลซานตง ประเทศจีน เราสามารถผลิตสายการลอกแผ่นไม้ เครื่องอบแผ่นไม้ เครื่องฉีดกาว เครื่องกดเย็น และเครื่องกดร้อน เป็นต้น

จนถึงขณะนี้เรามีลูกค้าจำนวนมากทั่วโลก เช่น สหรัฐอเมริกา ชิลี โคลอมเบีย บราซิล มาเลเซีย อินโดนีเซีย เวียดนาม รัสเซีย ยูเครน

โปแลนด์ สโลวาเกีย ตุรกี อียิปต์ กานา และเอธิโอเปีย เป็นต้น

钜ไสขอบไม้อัดของเราสามารถประมวลผลขนาด 4*8 ฟุต, 5*10 ฟุต และ 5*5 ฟุต

เครื่องยกแบบแมนนวลหรือแบบ vac-sorb

เครื่องกองไม้อัดอัตโนมัติ

ชิ้นส่วนไฟฟ้าของ Schneider

ให้บริการติดตั้งและฝึกอบรมฟรีเป็นเวลา 7 วัน

SIDE SAW 1

การปรับความกว้างของการตัด

สายการลอกไม้เนื้อบาง Hanvy

สายการลอกไม้เนื้อบางแบบไม่มีแกนนี้ได้รับความนิยมอย่างมากในอุตสาหกรรมไม้เนื้อบางและไม้อัดทั่วโลก

ใช้พื้นที่ 38x8 เมตร

สายการผลิตเต็มรูปแบบประกอบด้วย:

1. เครื่องป้อนบล็อกไม้ 2. เครื่องลอกเปลือกบล็อกไม้ 3. เครื่องป้อนบล็อกไม้ที่ลอกเปลือกแล้ว 4. เครื่องลอกไม้เนื้อบาง

5. เครื่องลำเลียงไม้เนื้อบาง 6. เครื่องตัดไม้เนื้อบางแบบ CNC 7. เครื่องกองไม้เนื้อบาง 8. เครื่องลำเลียงเศษเหลือทิ้ง

สายการกด HANVY

ควบคุมด้วย SIEMENS PLC มีการควบคุมแรงกด 5 ระดับ และข้อมูลโหมด 6 สำหรับไม้อัดคุณภาพสูง

ใบรับรอง CE คุณภาพดีที่สุดในประเทศจีน คลิกที่รูปด้านบนเพื่อดูรายละเอียดเพิ่มเติม

เรามีใบรับรอง ISO และ CE สำหรับเครื่องไม้อัดหลายชนิด ซึ่งสามารถบรรลุมาตรฐานคุณภาพของสหภาพยุโรปและสหรัฐอเมริกา

เครื่องจักร Hanvy plywood ถูกขายไปยังมากกว่า 60 ประเทศทั่วโลก เช่น ตุรกี รัสเซีย โปแลนด์ เยอรมนี บราซิล ยูเครน เม็กซิโก ออสเตรเลีย ตะวันออกเฉียงใต้ของเอเชีย แอฟริกา สหรัฐอเมริกา ฯลฯ

การรับประกัน 1 ปีสำหรับเครื่องทุกเครื่อง มีบริการติดตั้งและเปิดใช้งานโดยทีมวิศวกรมืออาชีพของเรา

Hanvy Machinery

หากคุณกำลังมองหาผู้จัดจำหน่ายเครื่องจักรไม้อัดชั้นนำที่มีความมุ่งมั่นในเรื่องคุณภาพและประสิทธิภาพ คุณควรพิจารณาและเครื่องตัดขนาดของพวกเขาที่มีนวัตกรรมใหม่

ในฐานะผู้ผลิตอุปกรณ์สำหรับการผลิตไม้อัดชั้นนำ Hanvy Machinery ได้สร้างชื่อเสียงให้กับตนเองในฐานะแบรนด์ที่น่าเชื่อถือและได้รับความไว้วางใจในอุตสาหกรรม โดยให้ความสำคัญกับนวัตกรรม การออกแบบ และความเชี่ยวชาญทางวิศวกรรม สินค้าที่ล้ำสมัยของพวกเขามีส่วนช่วยให้บริษัทหลายแห่งเพิ่มประสิทธิภาพและความกำไรได้อย่างมาก

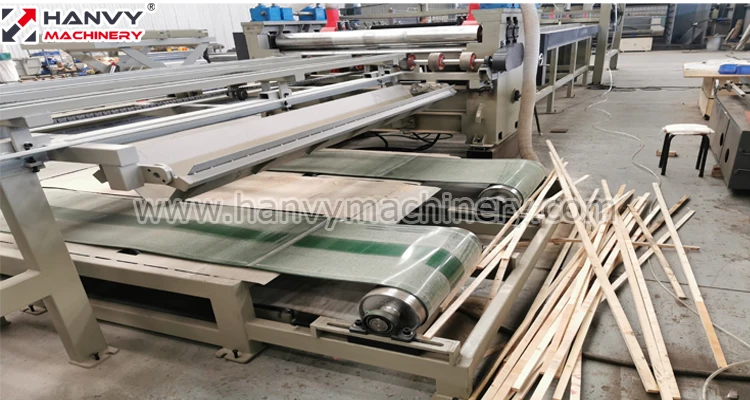

เครื่องตัดขนาดเล็กเป็นหนึ่งในผลิตภัณฑ์หลักของหลายแบรนด์ โดยให้ประสิทธิภาพที่ยอดเยี่ยม ขั้นตอนการทำงานง่าย และความแม่นยำสูง เครื่องนี้ถูกออกแบบมาโดยเฉพาะสำหรับการตัดไม้อัดในหลากหลายขนาด ตั้งแต่แผ่นเล็กไปจนถึงแผ่นใหญ่ ทำให้เหมาะสำหรับผู้ผลิตทุกขนาด

หนึ่งในคุณสมบัติเด่นที่สุดคือระบบควบคุม CNC แบบล้ำสมัย ซึ่ง Hanvy Machinery ระบบดังกล่าวช่วยให้ผู้ใช้งานสามารถวางแผนและตัดงานได้อย่างแม่นยำโดยไม่ต้องออกแรงมาก ตัวควบคุมช่วยให้มั่นใจว่าใบเลื่อยจะตัดได้อย่างถูกต้องและตรง ซึ่งจะนำไปสู่ไม้อัดคุณภาพสูงและลดเศษเหลือทิ้งลง

มีการดำเนินงานด้วยความเร็วสูง ซึ่งเพิ่มประสิทธิภาพในการผลิต ไม่ว่าการลงทุนของคุณจะมีขนาดใหญ่แค่ไหน เทคโนโลยีนี้สามารถช่วยลดค่าใช้จ่ายแรงงานขณะเดียวกันเพิ่มปริมาณการผลิตในสายการผลิต

ทรัพย์สินสำคัญอีกอย่างหนึ่งคือความสามารถในการตัดไม้อัดหลายประเภท เช่น แบบกาว ป้องกันการลื่น T และ G LVL และอื่น ๆ อีกมากมาย การปรับตัวได้ของเครื่องจักรหมายความว่าคุณจะสามารถปรับเปลี่ยนและเพิ่มประสิทธิภาพการผลิตได้อย่างรวดเร็ว ซึ่งรับประกันว่าคุณจะตอบสนองความต้องการของลูกค้าได้เสมอ

Hanvy Machinery มีบริการหลังการขายที่ยอดเยี่ยมพร้อมกับผลิตภัณฑ์และการสนับสนุนลูกค้า พวกเขาให้ความสำคัญกับการมอบบริการที่ครอบคลุมเพื่อสร้างความพึงพอใจและความสำเร็จของคุณ ตั้งแต่การติดตั้งและการฝึกอบรมไปจนถึงการบำรุงรักษาและการสนับสนุนอย่างต่อเนื่อง

โดยรวมแล้ว หากคุณกำลังมองหาทางเลือกในการอัพเกรดความสามารถในการผลิตไม้อัด Hanvy Machinery's Size Saw Cutting Machine เป็นการลงทุนที่ชาญฉลาด เครื่องจักรนี้มีประสิทธิภาพ แม่นยำ และหลากหลาย จะช่วยเพิ่มประสิทธิภาพของสายการผลิตและปรับปรุงคุณภาพของผลิตภัณฑ์ไม้อัดของคุณ

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ