เราให้บริการลูกค้าแบบครบวงจร ตั้งแต่เครื่องเดี่ยวไปจนถึงโครงการแบบครบวงจร ครอบคลุมกระบวนการผลิตทั้งหมด โดยเฉพาะอย่างยิ่งสายการผลิตอัตโนมัติเต็มรูปแบบ ไลน์เครื่องของเราประกอบด้วย เครื่องตัดไม้ท่อน เครื่องลอกแผ่นไม้ เครื่องอบแผ่นไม้ เครื่องเคลือบและกดไม้อัด เครื่องตัด เจียระไน และแต่งขอบไม้อัด เครื่องแยกประเภทไม้อัด เครื่องทำปูนหมักไม้อัด เครื่องแพ็คไม้อัด และเครื่องอื่นๆ

|

รุ่น

|

HG132/3000-8+1

|

HG182/3000-8+1

|

HG133/3000-8+1

|

HG134/3000-8+1

|

HG134/5000-6+1

|

HG134/6300-6+1

|

|

ประเภท

|

ล้อ 2 ชิ้น

|

ตาข่าย 2 ชิ้น

|

3 รอลเลอร์

|

ล้อ 4 ชิ้น

|

ล้อกว้าง 4 ชิ้น

|

ล้อกว้าง 4 ชิ้น

|

|

ความกว้างในการทำงาน

|

ขนาด 3000 มิลลิเมตร

|

ขนาด 3000 มิลลิเมตร

|

ขนาด 3000 มิลลิเมตร

|

ขนาด 3000 มิลลิเมตร

|

5000MM

|

6300มม.

|

|

หมายเลขแผ่นรอง

|

2

|

2

|

3

|

4

|

4

|

4

|

|

ความยาวส่วนทำความร้อน

|

16100mm

|

16100mm

|

16100mm

|

16100mm

|

12100mm

|

12100mm

|

|

ความยาวส่วนทำให้เย็น

|

ขนาด 2100 มิลลิเมตร

|

ขนาด 2100 มิลลิเมตร

|

ขนาด 2100 มิลลิเมตร

|

ขนาด 2100 มิลลิเมตร

|

ขนาด 2100 มิลลิเมตร

|

ขนาด 2100 มิลลิเมตร

|

|

ความจุในการอบแห้ง

|

2 ลบ.ม./ชม.

|

2 ลบ.ม./ชม.

|

3 ลูกบาศก์เมตร/ชั่วโมง

|

4 ลูกบาศก์เมตร/ชั่วโมง

|

6.5 ลูกบาศก์เมตร/ชั่วโมง

|

8.5 ลูกบาศก์เมตร/ชั่วโมง

|

|

การใช้ไอน้ำ

|

1780 กก./ชั่วโมง

|

1780 กก./ชั่วโมง

|

2580 กก./ชั่วโมง

|

3380 กก./ชั่วโมง

|

5040 กก./ชั่วโมง

|

6000 กก./ชั่วโมง

|

|

มอเตอร์ทั้งหมด

|

81.2กิโลวัตต์

|

85.5กิโลวัตต์

|

116.7กิโลวัตต์

|

141.2กิโลวัตต์

|

146.2กิโลวัตต์

|

257.2กิโลวัตต์

|

|

มอเตอร์ส่งกำลัง

|

11+2.2=13.2

|

7.5*2+2.2=17.5

|

11+7.5+2.2=20.7

|

11*2+2.2=24.2

|

11*2+2.2=24.2

|

11*2+2.2=24.2

|

|

มอเตอร์ทำความร้อน

|

7.5*8kw

|

7.5*8kw

|

11*8kw

|

15*8kw

|

18.5*6kw

|

37*6kw

|

|

มอเตอร์ระบายความร้อน

|

4*2kw

|

4*2kw

|

4*2kw

|

4*2kw

|

5.5*2kw

|

15*2kw

|

|

ความเร็วในการส่งข้อมูล

|

0-15 ม./นาที

|

0-25 ม./นาที

|

0-15 ม./นาที

|

0-15 ม./นาที

|

0-15 ม./นาที

|

0-15 ม./นาที

|

|

มิติรวม

|

29100*5260*3680มม.

|

29600*5260*3700มม.

|

29100*5260*4180มม.

|

29100*5260*4680มม.

|

25100*7060*4800มม.

|

25100*8560*4800มม.

|

|

น้ำหนัก

|

45000กก.

|

42000กก.

|

49000กก.

|

56000KG

|

75000KG

|

95000KG

|

ลักษณะหลัก

ความชื้นสม่ำเสมอของแผ่นไม้หลังจากการอบ

โครงสร้างกล่อง النفักรูปแบบพิเศษ ซึ่งสามารถป้องกันการอุดตันของแผ่นได้อย่างมีประสิทธิภาพ

พัดลมเหวี่ยงศูนย์กลางที่มีประสิทธิภาพสูงและแผงระบายความร้อนสำหรับผลผลิตแผ่นไม้ที่สูง

มาตรการฉนวนที่มีประสิทธิภาพช่วยลดการใช้พลังงานได้อย่างมีประสิทธิภาพ

พัดลมทั้งหมดอยู่ด้านเดียวกันเพื่อสะดวกต่อการบำรุงรักษา

บริการหลังการขาย

Hanvy มุ่งมั่นที่จะให้บริการผลิตภัณฑ์และบริการที่มีคุณภาพ

วิศวกรผู้เชี่ยวชาญพร้อมให้บริการติดตั้งเครื่องจักร การเปิดใช้งาน และการฝึกอบรม

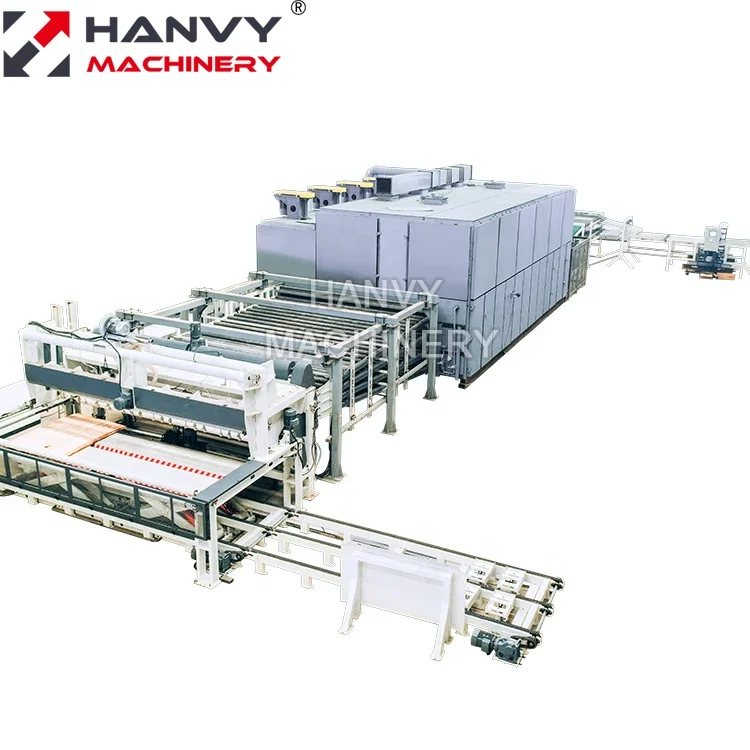

เครื่องอบแผ่นไม้เนื้อแข็งอัตโนมัติประสิทธิภาพสูงของ Hanvy Machinery ในกลุ่มเครื่องจักรไม้อัด เป็นบริการการอบแห้งชั้นยอดสำหรับตลาดแผ่นไม้เนื้อแข็ง ด้วยนวัตกรรมล้ำสมัยและความสามารถในการทำงานที่น่าเชื่อถือ เครื่องอบนี้เป็นทางเลือกที่สมบูรณ์แบบสำหรับกระบวนการผลิตไม้อัดคุณภาพสูง

เครื่องอบแผ่นไม้นี้ได้รับการออกแบบเพื่อให้มีประสิทธิภาพในการใช้พลังงานและการบำรุงรักษาในช่วงอายุการใช้งานน้อยมาก โดยมาพร้อมฟังก์ชันขนาดที่สามารถรองรับได้ถึง 3562mm ซึ่งรับประกันว่าสามารถจัดการแผ่นไม้อัดขนาดใหญ่ที่สุดได้ โครงสร้างของเครื่องจักรนี้ถูกออกแบบด้วยการเชื่อมอย่างแม่นยำ ซึ่งรับประกันความปลอดภัยและความแข็งแรง ทำให้เหมาะสำหรับความต้องการในการอบแผ่นไม้ที่หลากหลาย

หนึ่งในฟังก์ชันที่โดดเด่นคือการใช้ระบบแปลงความสม่ำเสมอสำหรับสายพานลำเลียง ซึ่งเพิ่มความแม่นยำในการอบและช่วยให้มีการเคลื่อนที่ของผลิตภัณฑ์อย่างนุ่มนวล นอกจากนี้ เทคโนโลยีนี้ยังส่งเสริมระบบควบคุมแรงตึงแบบอัตโนมัติที่รักษาความเรียบของไม้อัด ทำให้กระบวนการอบแห้งสม่ำเสมอทั่วทั้งแผ่น สินค้าชนิดนี้รับประกันคุณภาพระดับพรีเมียมสูงและความสวยงามของผลิตภัณฑ์สุดท้าย

อีกสิ่งที่น่าสนใจคือการใช้งานระบบควบคุมอุณหภูมิอัตโนมัติและระบบควบคุมความชื้น ซึ่งช่วยให้มั่นใจได้ว่ากระบวนการอบแผ่นไม้เนื้อบางจะสมบูรณ์แบบ ทำให้ประหยัดค่าพลังงานและป้องกันการสูญเสียของวัสดุโดยไม่จำเป็น ระบบควบคุมความชื้นใช้เซนเซอร์ความแม่นยำสูงที่ทำการตรวจสอบระดับความชื้นอย่างต่อเนื่องในระหว่างการอบ และให้ข้อมูลตอบกลับแบบเรียลไทม์สำหรับคอมพิวเตอร์ของเครื่องจักร ระบบควบคุมอุณหภูมิมีความแม่นยำและรับรองว่าแผ่นไม้เนื้อบางจะไม่ถูกสัมผัสกับสภาพแวดล้อมที่อาจทำลายคุณภาพสูงสุดของผลิตภัณฑ์

เกิดขึ้นกับระบบทำความร้อนในบ้านแบบล้ำหน้า เมื่อผ่านห้องอบแห้งที่มีความสามารถในการทำให้แห้งได้สูงถึง 50 ม. อบแห้งนี้ใช้อากาศร้อนเพื่อทำให้วัสดุไม้บางที่เปียกแห้งสนิท อากาศที่ใช้ในการทำให้แห้งจะถูกทำความร้อนโดยหม้อน้ำประสิทธิภาพสูงและถูกส่งไปยังห้องอบแห้ง ซึ่งจะระเหยความชื้นใด ๆ ในแผ่นไม้บาง ผลลัพธ์ของกระบวนการนี้คือแผ่นไม้บางที่มีคุณภาพดีเยี่ยม ซึ่งแห้งสนิทและพร้อมสำหรับการประมวลผลเพิ่มเติม

หากคุณกำลังมองหาบริการอบแห้งแผ่นไม้บางที่เชื่อถือได้ ซึ่งรวมเอาประสิทธิภาพ ความแม่นยำ และคุณภาพสูงไว้ด้วยกัน เครื่องอบแห้งแผ่นไม้บางอัตโนมัติประสิทธิภาพสูงจาก Hanvy Machinery ในประเทศจีนนี้คือตัวเลือกที่ดีที่สุดสำหรับคุณ

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ