ลอกไม้ได้อย่างสม่ำเสมอด้วยการควบคุม CNC

ช่วงการลอกสำหรับเส้นผ่าศูนย์กลางบล็อกไม้: 500mm-40mm

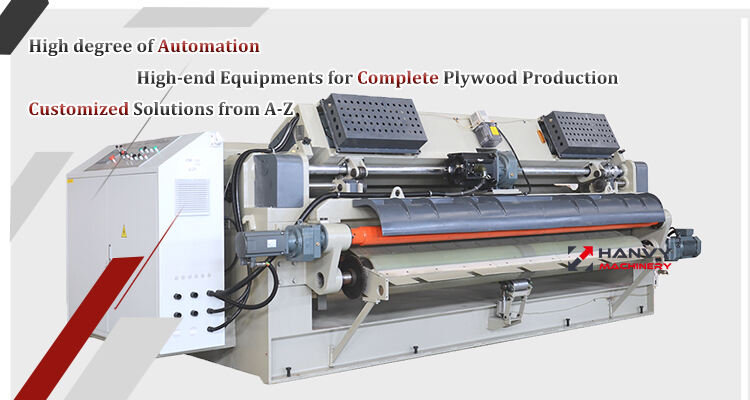

เครื่องตัดและลอกไม้เนื้อระบบ CNC ขนาด 8ft สำหรับสายการผลิตแผ่นไม้อัด

ตัวเลือก: ระบบควบคุม CNC, มอเตอร์เซอร์โวของซิเมนส์ - ระบบกดด้วยลม ช่องใบมีดปรับอัตโนมัติ มุมใบมีดปรับอัตโนมัติ ความเร็วสูงและแม่นยำ

เครื่องลอกแผ่นไม้แบบหมุน HANVY สำหรับหน้าไม้อัดเป็นเครื่องหลักสำหรับการผลิตแผ่นไม้บาง สามารถลอกบล็อกไม้ที่มีเส้นผ่านศูนย์กลางตั้งแต่ 500 มม. ถึง 40 มม. และเพิ่มการใช้งานไม้อย่างมีประสิทธิภาพ

เครื่องตัดและลอกไม้เนื้อระบบ CNC ขนาด 8ft สำหรับสายการผลิตแผ่นไม้อัด

|

รุ่น

|

HXQ2700

|

HXQ2000

|

HXQ1500

|

|

เส้นผ่าศูนย์กลางการทำงาน

|

Φ500 มม.

|

Φ500 มม.

|

Φ500 มม.

|

|

ความยาวการทำงานสูงสุด

|

2600 มม.

|

2000 มม.

|

1350 มม.

|

|

ความหนาของแผ่นไม้

|

0.5-3.0 มม.

|

0.5-3.0 มม.

|

0.5-3.0 มม.

|

|

เส้นผ่าศูนย์กลางแกนไม้

|

Φ 40 มม.

|

Φ 40 มม.

|

Φ 40 มม.

|

|

ความเร็วในการผลิตแผ่นไม้บาง

|

30-100 ม.╱นาที

|

30-100 ม.╱นาที

|

30-100 ม.╱นาที

|

|

กำลังมอเตอร์รวม

|

52 กิโลวัตต์

|

40 กิโลวัตต์

|

28.1 กิโลวัตต์

|

|

มิติรวม

|

5200x2500x1850 มม.

|

4500x2500 x1850 มม.

|

3800x2200x1850 มม.

|

|

น้ำหนัก

|

13500 กก.

|

12000 กิโลกรัม

|

9000 กก.

|

คุณสมบัติหลัก

คุณสมบัติหลัก เครื่องลอกแผ่นไม้เนื้อแข็ง

1. เส้นผ่าศูนย์กลางการทำงาน 500มม.

2. ความยาวการทำงานสูงสุด 2600มม.

3. ความหนาของแผ่นไม้ 0.5-3.0มม.

4. เส้นผ่าศูนย์กลางแกนไม้ 40มม.

5. ความเร็วในการผลิตแผ่นไม้ 30-100ม./นาที

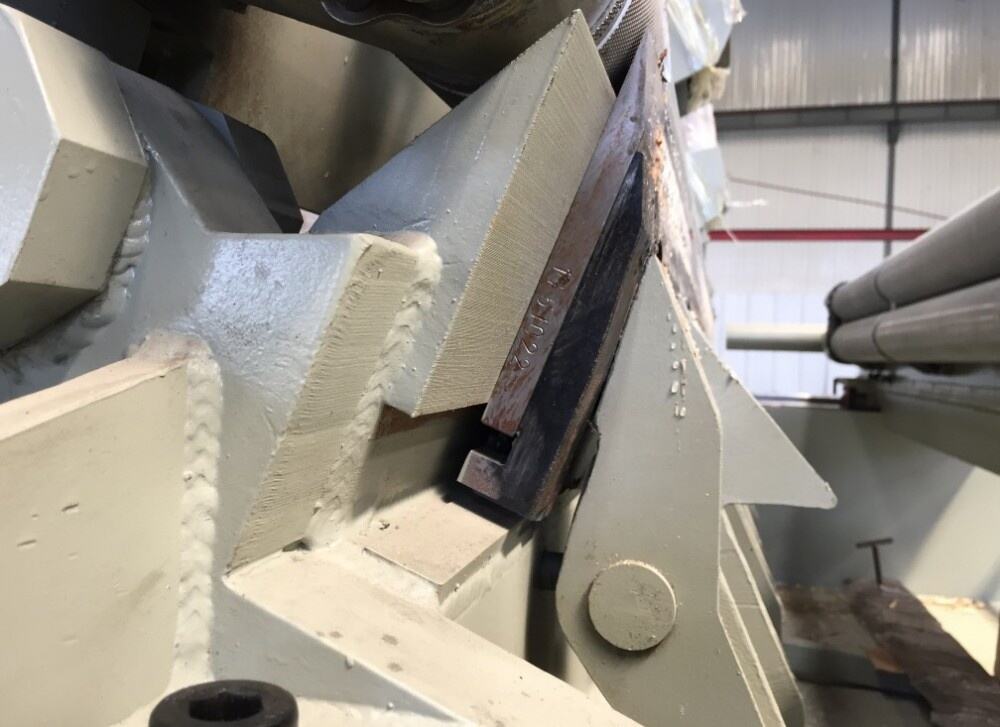

6. เกตเตอร์มีดแบบneumatic

7. วัสดุมีด: เหล็กกล้าโลหะผสม

8. เราให้บริการโซลูชันครบวงจรสำหรับสายการผลิตการลอกและตัดแผ่นไม้เนื้อ

ชนิด: เส้นผ่าศูนย์กลางการทำงานสูงสุด 500mm

ชนิดแกนเดี่ยว: เส้นผ่าศูนย์กลางการทำงานสูงสุด 800mm

ชนิดแกนคู่: เส้นผ่าศูนย์กลางการทำงานสูงสุด 1600mm

เครื่องลอกแผ่นไม้เนื้อแบบไม่มีแกนพร้อมตัด 2 ใน 1: เส้นผ่าศูนย์กลางทำงานสูงสุด 500mm

เครื่องกลึงลอกแผ่นไม้เนื้อด้วยไฮดรอลิกแบบจับเดี่ยว (ซ้าย)

เครื่องลอกแผ่นไม้เนื้อแบบไม่มีแกนรวมกับเครื่องตัด (ขวา)

คลิกภาพด้านล่างเพื่อดูหน้าสินค้ารายละเอียด

ลอกไม้ได้อย่างสม่ำเสมอด้วยการควบคุม CNC

ช่วงการลอกสำหรับเส้นผ่าศูนย์กลางบล็อกไม้: 500mm-40mm

ระบบ CNC และมอเตอร์เซอร์โวของ Mitsubishi นำเข้าจากญี่ปุ่นมีคุณภาพสูง อัตราความเสียหายต่ำ มีความแม่นยำในการทำงานสูงและอัตโนมัติสูง

ลูกกลิ้งกดแกนไม้เพื่อให้แรงสม่ำเสมอ ทำให้การลอกแผ่นไม้เสถียร

1. การกดใบมีดด้วยไฮดรอลิก;

2. เกียร์ขับเคลื่อน;

3. ลูกกลิ้งขับเคลื่อนที่ผ่านการบำบัดด้วยโครเมต

เกลียวนำส่งที่มีน็อตคู่สามารถทำให้การป้อนวัสดุแม่นยำมากขึ้น ดังนั้นผิวของไม้เนื้อบางจึงสามารถมีคุณภาพสูง

Hanvy Machinery เป็นผู้ผลิตต้นฉบับและมืออาชีพสำหรับเครื่องจักรผลิต Plywood เราสามารถจัดหาสายการลอกไม้เนื้อเต็มรูปแบบสำหรับการผลิต Plywood ให้กับคุณได้

สายการลอกไม้เนื้อบางแบบไม่มีแกนนี้ได้รับความนิยมอย่างมากในอุตสาหกรรมไม้เนื้อบางและไม้อัดทั่วโลก

ใช้พื้นที่ 38x8 เมตร

สายการผลิตเต็มรูปแบบประกอบด้วย:

1. เครื่องป้อนบล็อกไม้ 2. เครื่องลอกเปลือกบล็อกไม้ 3. เครื่องป้อนบล็อกไม้ที่ลอกเปลือกแล้ว 4. เครื่องลอกไม้เนื้อบาง

5. เครื่องลำเลียงไม้เนื้อบาง 6. เครื่องตัดไม้เนื้อบางแบบ CNC 7. เครื่องกองไม้เนื้อบาง 8. เครื่องลำเลียงเศษเหลือทิ้ง

เราได้สะสมประสบการณ์มากกว่า 30 ปี และสามารถสร้างผลกระทบอย่างมีนัยสำคัญในตลาดระหว่างประเทศได้อย่างสำเร็จ ผลิตภัณฑ์ทั้งหมดของเราประกอบด้วยเครื่องจักร เช่น เครื่องลอกเปลือกไม้ เครื่องปอกแผ่นไม้เนื้อแข็ง เครื่องอบแผ่นไม้ เครื่องทา glue เครื่องกดไม้อัดแบบเย็น เครื่องกดความร้อน เครื่องเลื่อยไม้อัด D.D. เครื่องจักรบ้านไม้ และ เลื่อยและเครื่องขึ้นรูปไม้ท่อน

เครื่องจักร Hanvy plywood ถูกขายไปยังมากกว่า 60 ประเทศทั่วโลก เช่น ตุรกี รัสเซีย โปแลนด์ เยอรมนี บราซิล ยูเครน เม็กซิโก ออสเตรเลีย ตะวันออกเฉียงใต้ของเอเชีย แอฟริกา สหรัฐอเมริกา ฯลฯ

การรับประกัน 1 ปีสำหรับเครื่องทุกเครื่อง มีบริการติดตั้งและเปิดใช้งานโดยทีมวิศวกรมืออาชีพของเรา

Hanvy Machinery

แนะนำเครื่องปอกและตัดไม้เนื้อแน่น CNC ความยาว 8 ฟุต ซึ่งเป็นเครื่องมือชั้นนำในกระบวนการผลิตแผ่นไม้เนื้อแน่นจากแบรนด์คุณภาพเยี่ยม เครื่องนี้มีความสามารถในการปอกและตัดแผ่นไม้ยาว 8 ฟุต ทำให้การทำงานรวดเร็ว สะดวก และมีประสิทธิภาพ

รับประกันความแม่นยำและความถูกต้องในการปอกและการตัดแผ่นไม้เนื้อแน่นด้วย Hanvy Machinery เทคโนโลยี CNC (Computer Numerical Control) นอกจากนี้ยังสามารถตั้งโปรแกรมความหนาได้ตามต้องการสำหรับแต่ละการปอกและการตัด ทำให้ได้แผ่นไม้เนื้อแน่นที่มีคุณภาพสูงและสม่ำเสมอสำหรับการผลิตไม้อัด

ทุกวินาทีมีความสำคัญ และอุปกรณ์นี้ช่วยให้ผู้ผลิตสามารถผลิตไม้เนื้อแท้ได้ในปริมาณมากภายในระยะเวลาอันสั้นในการผลิตแผ่นไม้เนื้อแท้ อุปกรณ์ที่แข็งแรงและมั่นคงช่วยให้การทำงานลื่นไหล พร้อมมอบประสิทธิภาพที่ยอดเยี่ยมและสม่ำเสมอ

เครื่องยนต์ทรงพลังขับเคลื่อนเครื่องจักรสามารถจัดการกระบวนการที่ท้าทายได้โดยไม่ลดคุณภาพของผลผลิต เครื่องมีใบมีดที่ทนทานสามารถตัดผ่านวัสดุไม้ที่หนาแน่นได้อย่างง่ายดาย ทำให้เหมาะสำหรับความต้องการในการผลิตแผ่นไม้เนื้อแท้หลากหลายประเภท

ใช้งานง่าย มีขั้นตอนการปฏิบัติงานที่เรียบง่าย และผู้ใช้งานสามารถควบคุมได้สะดวก การออกแบบตามหลักสรีรศาสตร์ช่วยให้ผู้ปฏิบัติงานรู้สึกสบายเมื่อใช้งานเป็นเวลานาน ลดความเหนื่อยล้าที่เกี่ยวข้องกับการแปรรูปไม้เนื้อแท้

ติดตั้งและจัดเรียงได้ง่าย ใช้พื้นที่ในโรงงานผลิตเพียงเล็กน้อย มีดีไซน์สวยงามและกะทัดรัด เครื่องนี้เหมาะสำหรับโรงงานผลิตไม้อัดและเนื้อไม้บางขนาดเล็กถึงขนาดกลางที่ต้องการผลผลิตคุณภาพสูงตามข้อกำหนดของอุตสาหกรรม

เครื่องปอกและตัดแผ่นไม้เนื้อบางระบบ CNC ความยาว 8 ฟุต จาก Hanvy Machinery เป็นเครื่องจักรที่ยอดเยี่ยมซึ่งปฏิวัติวงการการผลิตแผ่นไม้เนื้อบางสำหรับไม้อัด ด้วยคุณสมบัติทางเทคโนโลยีขั้นสูง การออกแบบตามหลักสรีรศาสตร์ โครงสร้างแข็งแรง และอินเทอร์เฟซที่ใช้งานง่าย ทำให้เครื่องนี้เป็นการลงทุนที่คุ้มค่าสำหรับผู้ผลิตแผ่นไม้เนื้อบางที่ต้องการความแม่นยำ ความรวดเร็ว และประสิทธิภาพในกระบวนการทำงาน Hanvy Machinery ได้พัฒนาเครื่องจักรชั้นยอดที่ตอบโจทย์ตามชื่อเสียงของแบรนด์อย่างแท้จริง