Opis:

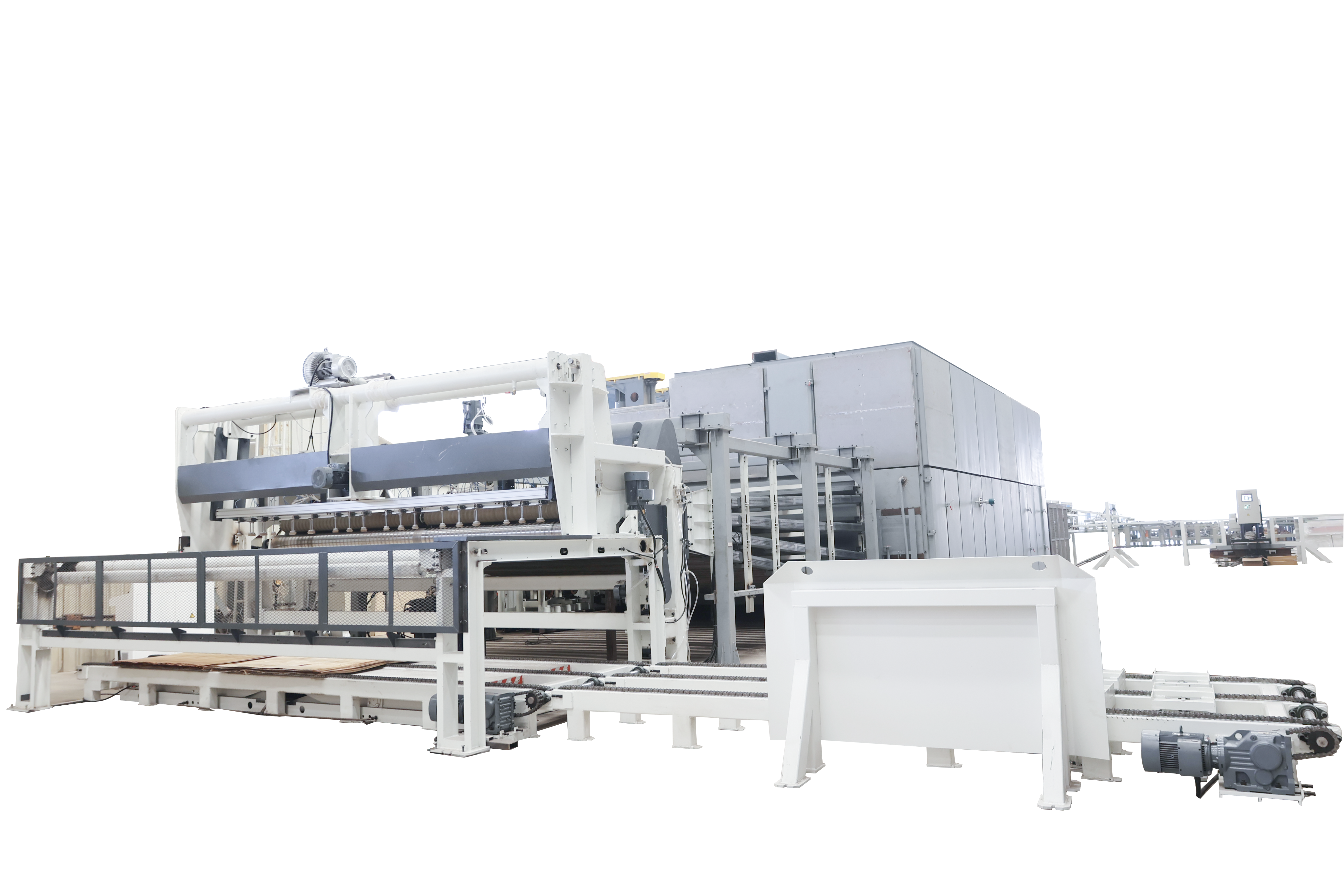

Sušenje jezgra je jedan od ključnih koraka u proizvodnji jezgra. Glavna cilj sušnog procesa je da se proizvede visokokvalitetno osušeno jezgro sa najvećom mogućom efikasnošću. To se postiže korišćenjem vrelog i vlage punog zraka unutar sušioca kako bi se uklonila vlaga iz jezgra i smanjila sadržina vode na optimalni nivo.

Možemo ponuditi različite serije linija za sušenje jezgra prema izboru kupca, a takođe možemo klasifikovati osušeno jezgro u različite vrste jezgra kombinovanjem sa analizatorima vlage, analizatorima kvaliteta i drugim opremama. Dostupno je za proizvodnju folijata ili LVL.

Glavne karakteristike:

*Jednolika sadržina vlage u jezgru nakon sušenja

*Jedinstvena struktura jet box-a koja efektivno sprečava zaklepavanje jezgra

*Efikasan centrifugalni ventilator i toplinski sink zaradi velikog izlaznog jezgra

*Efikasne izolacione mere učinkovito smanjuju potrošnju energije

*Svi ventilatori su sa iste strane za lakše održavanje

*Štednja rada, cijela proizvodna linija zahteva samo 1 do 2 radnika za rad

*Sistem preklapanja ulaza (opcioni), koji može povećati proizvodnju do 10%

*Sistem upravljanja temperaturom i vlažnošću zraka (opcioni), automatski prilagođava temperaturu i vlažnost u sušionici, štedi do 20% potrošnje energije po kubnom metru folije koja se proizvodi

*Automatski sistem gašenja vatre (opcioni)

Specifikacije:

| Model | HG132/3000-8+1 | HG182/3000-8+1 | HG192/3000-8+1 | HG133/3000-8+1 | HG183/3000-8+1 | HG193/3000A-8+1 | HG193/3000B-8+1 | HG134/3000-8+1 | HG184/3000-8+1 | HG194/3000-8+1 | HG134/5000-6+1 | HG134/5900-6+1 | HG134/6300-6+1 | |

| Tip | - | 2 Rolere | 2 Mreže | Mreža&Valj | 3 valjka | 3 Mreže | 1 Mreža&2 Valjka | 2 Mreže&1 Valjak | 4 Rolere | 4 Mreže | 2 Mreže&2 Valjka | Široki 4 Rolere | Široki 4 Rolere | Široki 4 Rolere |

| Радна ширина | mm | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 5000 | 5900 | 6300 |

| Broj deskova | - | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 |

| Dužina grejanja | mm | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 12100 | 12100 | 12100 |

| Dužina hlađenja | mm | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 |

| Sposobnost sušenja | m³/h | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 6.5 | 7.5 | 8.5 |

| Potrošnja pare | килограми/ч | 1780 | 1780 | 1780 | 2580 | 2580 | 2580 | 2580 | 3380 | 3380 | 3380 | 5040 | 5460 | 6000 |

| Ukupni motor | KW | 81.2 | 85.5 | 80.7 | 116.7 | 120.7 | 116.7 | 120.7 | 141.2 | 160.2 | 156.2 | 146.2 | 257.2 | 257.2 |

| Motor za prenos | KW | 11+2.2=13.2 | 7.5*2+2.2=17.5 | 11+7.5+2.2=20.7 | 11+7.5+2.2=20.7 | 7.5*3+2.2=24.7 | 7.5+11+2.2=20.7 | 7.5*3+2.2=24.7 | 11*2+2.2=13.2 | 7.5*4+2.2=32.2 | 7.5*2+11+2.2=28.2 | 11*2+2.2=24.2 | 11*2+2.2=24.2 | 11*2+2.2=24.2 |

| Grejanje motor | KW | 7.5*8 | 7.5*8 | 7.5*8 | 11*8 | 11*8 | 11*8 | 11*8 | 15*8 | 15*8 | 15*8 | 18.5*6 | 37*6 | 37*6 |

| Мотор за хлађење | KW | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4.2 | 4*2 | 4*2 | 5.5*2 | 15*2 | 15*2 |

| Brzina prenosa | m/min | 0-15 | 0-25 | 0-25/0-15 | 0-15 | 0-25 | 0-25/0-15 | 0-25/0-15 | 0-15 | 0-25 | 0-25/0-15 | 0-15 | 0-15 | 0-15 |

| Ukupne dimenzije | mm | 29100*5260*3680 | 29600*5260*3700 | 38195*5260*3730 | 29100*5260*4180 | 32600*5260*4900 | 38195*5260*4230 | 38195*5260*4430 | 29100*5260*4680 | 32600*5260*5170 | 38195*5260*4930 | 25100*7060*4800 | 25100*8160*4800 | 25100*8560*4800 |

| Težina | Kg | 45000 | 42000 | 43500 | 49000 | 46000 | 47500 | 47000 | 56000 | 52000 | 59000 | 75000 | 89000 | 95000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ