Linija za razvrščanje drvene ploščade

Dobavno čas je znotraj 90 dni, glede na količine

Ladjarne v Qingdao, Tianjin, Guangzhou, katere koli ladjarne v Kitajskem so na voljo

Imamo kupce v ZDA, Rusija, Turčija, Poljska, Ukrajina, Etiopija, Gana, Egipt, Indonezija, Vietnam in Malezija itd. Večina jih je proizvajalcev brezglobnih plošč

3. Dobrodošli ob obisku in osebni razpravi

1. Izvršili bomo narocilo v skladu s pogodbo

2. Sprejmemo kaznovanje za zakasnitev dostave.

3. Osnovne skice bomo poslali v mesecu po prejemu narocila.

Posleprodajno:

1. Najprej potrdite obdobje namestitve.

2. Ponudimo 3 dni brezplačne storitve za poganjanje.

3. Naš inženir se ne bo vrnil, dokler stroji ne bodo delovali glodno.

garančni period trajajo eno leto

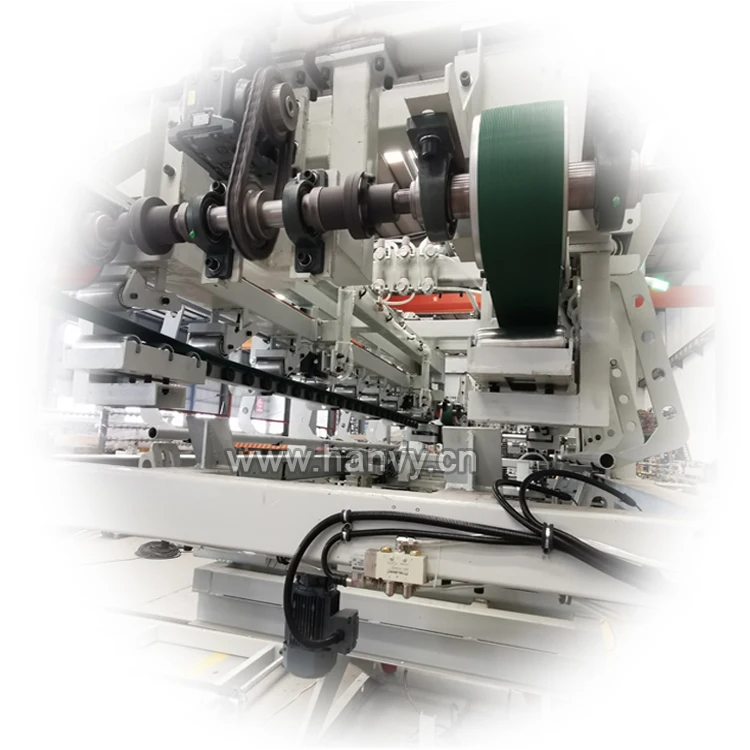

Predstavljamo novo izdelek Hanvy Plywood Machinery - 4 in 6 Kontejnerjev vrstni red razvrščanja papirnate, ki je zadnji dodatek v svoji ponudbi. Ta vrhunski stroj je idealen za katere koli proizvodnjo papirnate, ki cenijo učinkovitost in produktivnost.

S svojim obsežnim strokovništvom v papirnatem sektorju so zasnovali ta vrstni red razvrščanja, ki lahko izpolni zahteve katere koli obravnave papirnate. Bil je opremljen s najnovejšo tehnologijo, ki zagotavlja natančen in točen proces razvrščanja, kar pomeni, da bodo končni izdelki vedno odlične kakovosti, ki izpolnjuje očakovanja strank.

Ponuja več funkcij, ki ga razlikujejo med konkurencijo. Modularna zasnova omogoča fleksibilnost pri konfiguraciji, kar dovoljuje prilagajanje na podlagi zahtev fabrike. Uporabniški vmesnik je prijazen, kar poenostavi nadzor in spremljanje postopka razvrščanja, zagotavljajoč učinkovito izvajanje.

Ena ključnih lastnosti tega stroja je visokospečna transportska trakovanja. Ta tehnika je poganjana s močnim motorjem, ki zagotavlja hitro prevoz drvene plošče skozi vrstilo. Trakovanje je tudi zasnovano tako, da lahko obrača z različnimi velikostmi drvenih plošč, kar ga dela zelo versatilen.

Bil je opremljen z naprednimi senzorji ravni, ki zaznavajo defekte, kot so čvorovi, trske in pukotine. Ti so avtomatsko razvrščeni in umaknjeni v ustrezne posode. Končna kakovost se pregleda ročno, da se prepričamo, da noben defekt, ki bi bil zamujen s senzorji, ni propustl pred pošiljanjem izdelkov.

Bilo je zgrajeno z trdno namero na misli. Bilo je izdelano iz visokokakovostnih materialov, ki so priznani zaradi svoje odpornosti in moči. Oprema je tudi enostavna v ohranjanju, zahteva minimalno vzdrževanje in zasleno bo trajala številne leta z primerno skrbjo.

Plywood Sorting Line s 4 in 6 kontejneri od Hanvy Plywood Machinery je prelom v industriji obdelave drvenih plošč. Ponuja neprimerljivo učinkovitost in proizvodnost, s čimer delavnici shranjuje čas in denar. S leti izkušenj Hanvy Machinery v tej industriji lahko podjetja zaupajo, da pridobivajo izdelek, ki je bil zgrajen tako, da bo trajal. Izberite Hanvy Machinery in vložite v izdelek, ki bo vaše podjetje pripeljal na višjo stopnjo.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ