Popis:

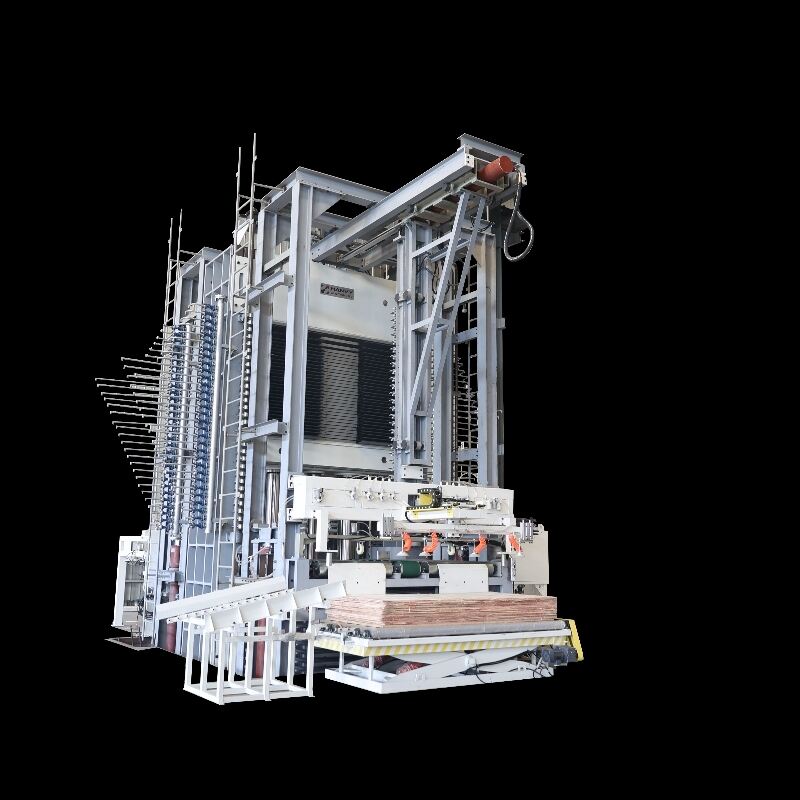

Úplne automatická výrobná linka na tlačenie plášťov revolučne zvyšuje efektivitu a kvalitu výroby plášťov. S touto modernou sústavou môže jeden operátor sledovať celý proces, od nakládania predtlačených baliek plášťov po vykladanie hotových panelov na zasadenie.

V srdci operácie je sofistikovaná horká tlačnica, pečlivo navrhnutá pre optimálnu výkonoschopnosť. Proces horečného tlačenia je precízne nastavený tak, aby každý panel bol podrobený ideálnemu kombinovanému tlaku, teplote a času, čo viedlo k vynikajúcej kvalite plášťov.

Okrem toho systém ponúka flexibilitu s volitelným automatickým vybavovaním a vykladaním. Táto ďalšia funkcia ešte viac zjednodušuje pracovný postup, zníži manuálny námah a maximalizuje produkčnosť.

S touto modernou výrobnou linkou môžu výrobci očakávať zvýšenú výstavbu, lepšiu konzistenciu produktu a snížené pracovné náklady.

V prípade, že sa použije tento predpis:

| model | HYZ2148-20A6-60 | HYZ2148-30A6-60 |

| Veľkosť horkého platen | 2700*1370*42 mm | 2700*1370*42 mm |

| Rozmer produktu | 4*8 ft | 4*8 ft |

| otváranie | 60 mm | 60 mm |

| počet otvorov | 20 | 30 |

| Priemer plunžerového valca | φ380mm*2/φ180mm*1 | φ360mm*2/φ220mm*1 |

| Pracovný chod | 1200 mm | 1800 mm |

| Kapacita | 6000 KN | 6000 KN |

| Max. pracovný tlak | 25 MPa | 25 |

| Motor | 80 kw | 134 kw |

| Rýchlosť zatvárania | 9 m/min | 9 m/min |

| Celkové rozmery | 8990*7970*6190 mm | 8990*7970*7180 mm |

| Hmotnosť | 68000 kg | 92000 kg |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ