China Plywood Machinery Supplier Veneer Peeling Production Process Line

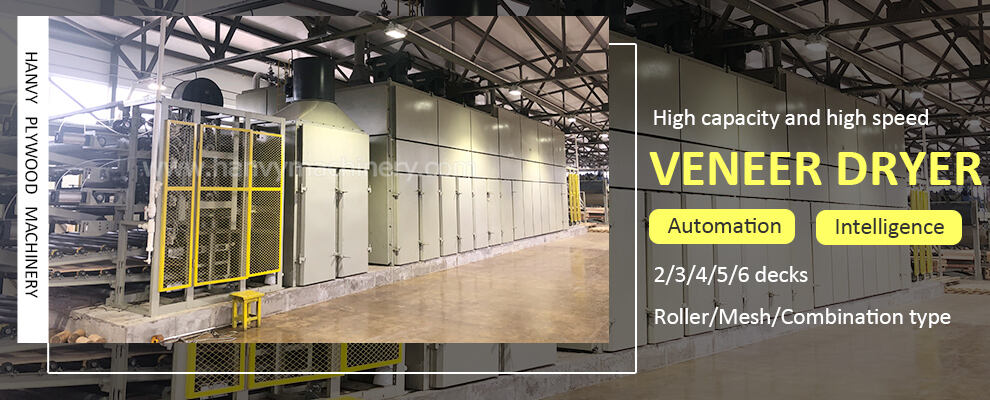

Hanvy Machinery, is the original and professional manufacturer for plywood production machinery, we can supply you full wood veneer peeling line for plywood production.

This veneer spindle less peeling line is very popular in veneer and plywood industry worldwide.

It occupies space 38x8m.

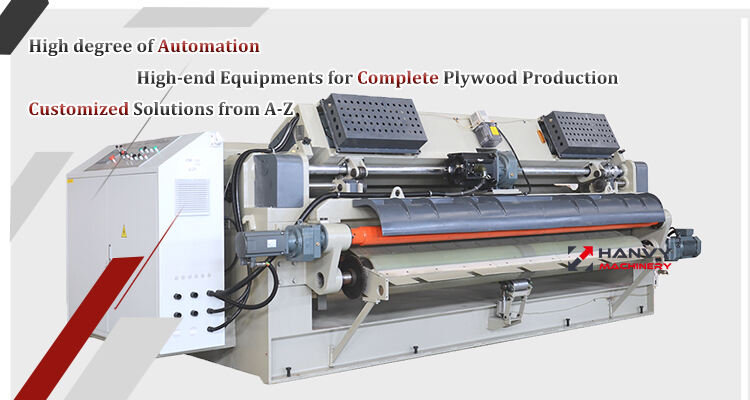

Plywood Machinery Supplier Spindle less Peeling Machine for Veneer Production Line

China Plywood Machinery Supplier Veneer Peeling Production Process Line

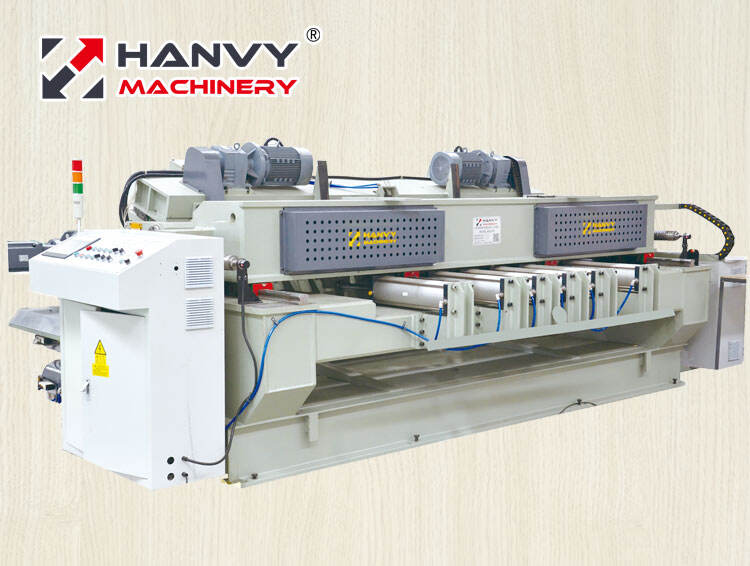

The full line includes:

1. Log feeder 2. Log debarker 3. Debarked log feeder 4. Veneer peeling machine

5. Veneer conveyor 6. CNC veneer rotary clipper 7. Veneer stacker 8. Waste conveyor

China Plywood Machinery Supplier Veneer Peeling Production Process Line,

well sold to over 50 countries, such as Brazil, USA, Australia, Ghana, Egypt, Malaysia, Ethiopia, Poland, Slovakia, Russia, Turkey, Ukraine, Chile, Indonesia, South Africa, Colombia, etc.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ