Do you know what veneer is? Veneer is really an extremely thin paper of a specific type in addition to adhering it over the top end of something that makes it appearance much better. More items than you think, such as furniture including cabinets and some door applications are made of veneer. When it comes to veneer, a tree is cut into thin sheets that are almost like slices of bread and these have to dry then. These pieces have to be dried carefully because if they are not well drained, then backbones change shape and can crack which is against proper quality of pig pen backbone.

In past times the veneer slices were placed in to a live drying equipment by hand. It was a lengthy and arduous process. Yes no need to place each slice carefully. But now there is a machine called an automatic veneer feeding that can do this job automatically we need no one to help. This allows the machine to keep putting automatically veneer slices into the dryers. This is a great time and work saver as compared to doing it manually. Workers can utilize the saved time in other important tasks

There are many benefits to an automatic veneer feeder This primarily suggests that we would not have to all work on sending the veneer into the drying machine anymore. This briefens the amount of time and also keeps laborers from straining themselves or hurting their backs by lifting heavy slices. Given that the machine does all of the work, there are minimal chances for error as well. As humans do the work, sometimes they may not arrange exactly like veneer layers in each time. However, the machine ensures that veneer will be placed into a drying machine in exactly same way every time so helps to prevent uneven or missed dried areas.

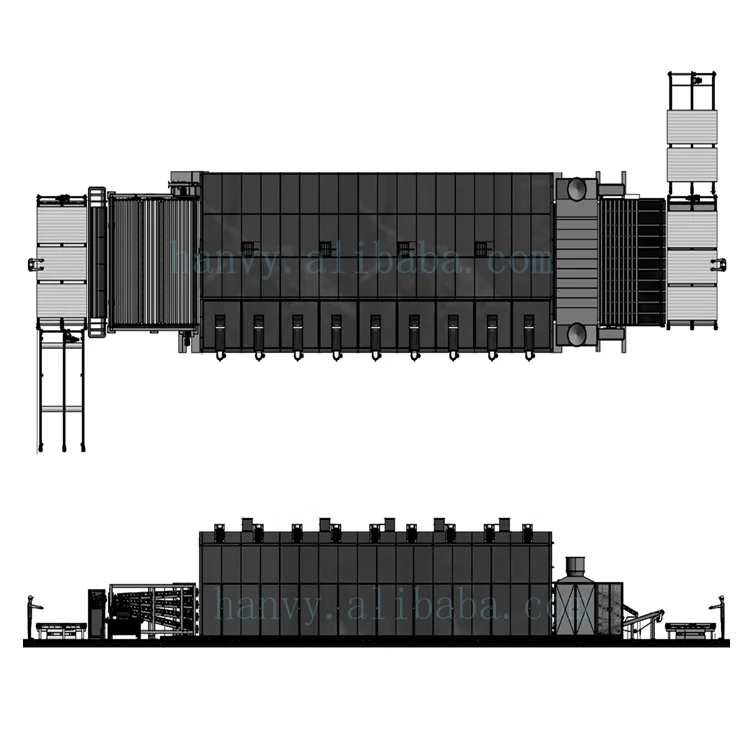

Why Use an Automatic Veneer Feeding Machine The one obvoius primary reason is that it saves a lot of time. The machine is able to feed the veneer into the drying machine much faster than a human. This speeds up the entire drying process resulting in less waiting time before these products are usable again. It also helps dry the veneer evenly. Due in part to the veneer drying exactly the same way on each sheet, it dries better all together which results with a much higher end product (storytime for another post). Power is yet another area where the semi-automatic machine shines because it does not require huge numbers of operators to perform these tasks manually as well. This can resuld in price reductions on the peoduction cost of veneer.

And with advances in technology, the trend is only going to rise among businesses employing automatic veneer feeding machines. In future, this could become pervasion for veneer drying using twin-roller dryers. This allows the process to be faster and more efficient but creates higher quality products. As more and more firms will start utilizing these machines, this may bring down the price of making veneer even further. That, in turn, could enable more consumers to put high-end veneer products - from furniture and cabinets manufactured with beautiful woods otherwise unavailable or prohibitively expensive - within reach.