Penggunaan Produk - Hanvy Plywood Machinery Proses Pengupasan Veneer

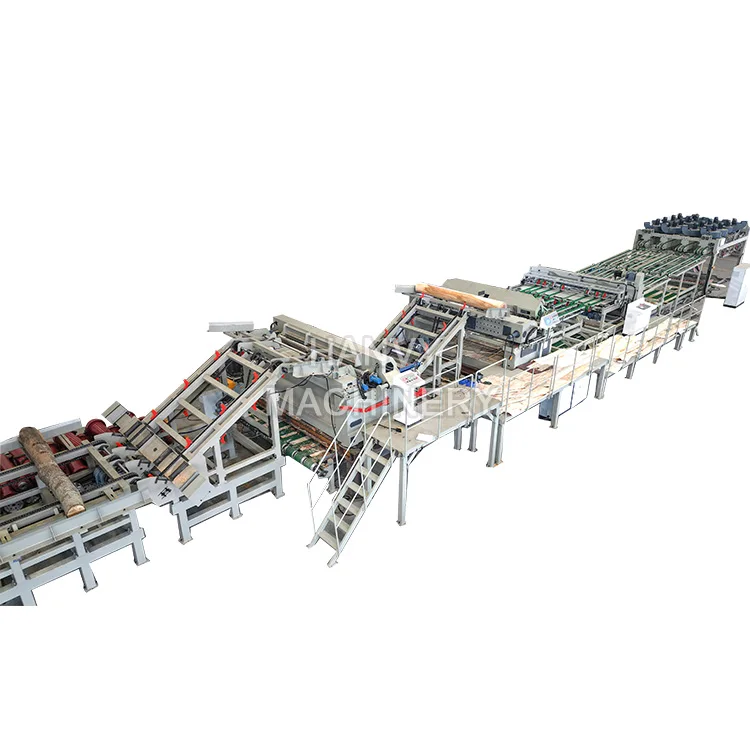

Hanvy Machinery adalah pembuat asal dan profesional untuk mesin pengeluaran plywood, kami boleh menyediakan kepada anda garis penuh untuk pengupasan kayu veneer bagi pengeluaran plywood

Garisan pengupasan spindle kurang veneer ini sangat popular dalam industri veneer dan papan plywood di seluruh dunia

Garisan penuh termasuk:

1. Pemberi log 2. Pengupas log 3. Pemberi log yang telah dikupas 4. Mesin pengelupas veneer

5. Penghantaran veneer 6. Penjepit putar CNC veneer 7. Penumpuk veneer 8. Penghantaran buangan

Hanvy 8FT Garisan Proses Pengupasan Veneer Untuk Veneer

Garis pengupasan veneer yang lengkap terdiri daripada empat bahagian utama,

1. PEMBALEK LOG

2. MESIN PENGUPAS VENEER

3. PENGGUNTING ROTARI VENEER CNC

4. PENYUSUN VENEER OTOMATIK (Pilihan), Penjimapan Veneer Manual adalah pilihan

Bahagian ini terdiri daripada cas log, konveyor sisa dan pengupas kulit log

Garis pelupusan getah ini boleh memproses diameter maksimum log pada 500mm, panjang log pada 1400mm

Kedua-dua hujung log mempunyai diameter yang sama

Garis pelupusan getah --- pelupus getah

Pelupus getah adalah mesin inti bagi garis pelupusan getah. Ini adalah pelupus getah tanpa poros berkelajuan tinggi, yang boleh memproses diameter maksimum log inti pada 480 mm, panjang log pada 1400 - 2700 mm. Ketebalan getah pada 0.5 - 3.0 mm, kelajuan pelupusan 30-100 m/min

Dengan Siemens PLC, sistem Mitsubishi adalah pilihan

|

Nama produk

|

Hanvy 8FT Pelupusan Getah Tanpa Poros Untuk Kilang Plywood

|

|

Jenis Pelupusan

|

|

|

Jenis Pokok

|

Birch, Poplar, Pine, Eucalyptus dll

|

|

Diameter log maks.

|

500mm

|

|

Ketebalan veneer

|

0.5-3.0mm

|

|

Lebar dan panjang kertas kayu

|

4*8ft, 4*4ft

|

|

Jenis pengumpulan

|

Penyusun kertas kayu automatik atau manual

|

|

Kapasiti anggaran kertas kayu

|

3cbm/j

|

Garis pelupusan kertas kayu-CNC penjepit putaran kertas kayu

Untuk memotong kertas kayu pada lebar yang berbeza

Min, lebar adalah 200 mm

Tiga bilah, 100 m/minit, servo Yaskawa, dengan konveyor pemberi dan konveyor pengeluar

|

Model

|

HJG2700

|

Dimensi Keseluruhan

|

6300x3835x1677mm

|

|

Maks. Lebar Kerja

|

2650mm

|

Berat

|

4300kg

|

|

Kelajuan Pemotongan

|

100m/min

|

Motor pemotong

|

motor servo yaskawa

|

|

Kuasa Motor

|

12KW

|

|

|

Garis Pelapisan Veneer - tiga tingkat penumpuk veneer automatik

Jenis kerja Vac-sorb

Kuasa motor 3 kw

Sistem kawalan Siemens

Dengan satu tong atau pelbagai tong

Untuk menghemat lebih banyak kos tambang

|

Model

|

HDD1126/4-1

|

Ketinggian tumpukan maks.

|

1000mm

|

|

Kedua kerja

|

2200-2600mm

|

Motor

|

25.8kw

|

|

Ketebalan veneer

|

1.0-3.0mm

|

Sistem

|

Siemens

|

|

Kelajuan

|

140m/min

|

|

|

Kami mempunyai pembeli di USA, Russia, Turkey, Poland, Ukraine, Ethiopia, Ghana, Egypt,

Indonesia, Vietnam dan Malaysia dll. Majoritinya adalah pengeluar plywood

Kami mempunyai banyak pengalaman dalam bidang ini, dan kami akan dengan senang hati berkongsi kes berjaya kami dengan anda

Apabila berbicara tentang pengeluaran papan plywood berkualiti tinggi, mempunyai mesin yang betul boleh membuat perbezaan yang besar. Di sinilah Hanvy Machinery hadir dengan Mesin Plywood 4 kaki 8 kaki dan 10 kaki Proses Pengupasan Veneer. Dengan mesin inovatif dan boleh dipercayai ini, anda boleh yakin bahawa proses pengeluaran plywood anda akan menjadi cekap, berkesan, dan berkualiti tinggi.

Jadi, apa sebenarnya Mesin Plywood 4 kaki 8 kaki dan 10 kaki Proses Pengupasan Veneer dari Hanvy Machinery? Secara asasnya, ia merujuk kepada pengeluaran veneer yang licin, malar, dan seragam yang penting untuk mencipta plywood yang kuat dan tahan lama. Mesin ini menggunakan teknologi terkini untuk mengupas lapisan luarnya daripada batang kayu, mencipta lapisan nipis yang akan digunakan untuk membuat veneer.

Salah satu ciri khas yang menonjol dari ini adalah keversatilannya. Mesin ini adalah pilihan yang baik untuk semua jenis pengeluar, dengan kemampuan untuk memproses log dengan saiz dan ketebalan yang berbeza. Baik anda menghasilkan perabot, peti, atau bahan binaan, anda akan mendapati bahawa Mesin Plywood Hanvy adalah kaedah yang boleh dipercayai dan cekap untuk mencipta lapisan yang sempurna mengikut keperluan anda.

Kelebihan lain daripada ini adalah ke mudahannya. Dengan kawalan yang mudah dan arahan yang jelas, pengendali boleh dengan pantas mempelajari cara menggunakan peralatan ini secara efektif, malah mereka yang tidak berpengalaman. Selain itu, dengan ciri keselamatan terbina dan prestasi yang boleh dipercayai, anda boleh yakin bahawa pasukan anda bekerja dengan alat terbaik yang ada.

Tentu saja, apabila berbicara tentang mesin, kualiti adalah kunci utama. Kami hanya menggunakan bahan dan komponen berkualiti tertinggi untuk menghasilkan Mesin Plywood ini. Setiap bahagian peralatan ini telah dibuat untuk memberikan hasil yang konsisten dan boleh dipercayai, dari struktur logam yang tahan lama hingga alat pemotong moden dan bilah pisau.

Jadi, sama ada anda merupakan pembuat plywood berpengalaman atau baru bermula dalam industri ini, Mesin Plywood Hanvy dengan proses Peeling Veneer 4 kaki 8 kaki dan 10 kaki adalah produk yang boleh anda percayai. Dengan reka bentuknya yang inovatif, operasi yang mudah, dan komponen berkualiti tinggi, mesin ini akan membantu anda mencipta veneer berkualiti tinggi yang diperlukan untuk menghasilkan plywood yang kuat dan tahan lama.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ