Produkta pielietojums

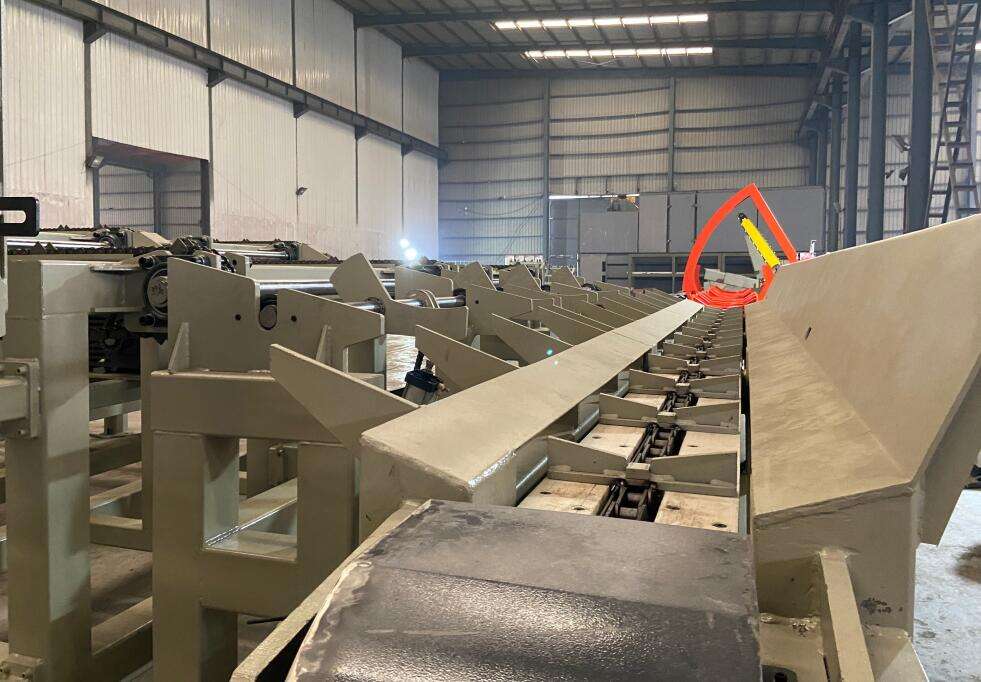

Plywood Lumber Chain Saw Cutting Machine Sawing Line Log Cut Off Saw for Sale

2. Pirmajā horizontālā padevē tiek izmantots 4-šainu tips, lai glabātu un klasificētu koku bilas.

3. Stepper logs feeder, lai nodrošinātu, ka koki iet ilgstošajā pārvades transportētājā viens pēc otra. Augsta darba efektivitāte.

4. Sīpols, divi veidi: ķe Edwards vai apļa sīpolu tips, jebkurs ir derīgs.

5. Izmaiņas daļas, ar koka pagriešanas ierīci.

Polija, Slovākija, Turcija, Eģipte, Gana un Etiopija utt.

Plywood Lumber Chain Saw Cutting Machine Sawing Line Log Cut Off Saw for Sale

Apļveida ogas griešanas līnija, labi piemērota mazāka diametra ogu griešanai, augsts kapacitātes.

Darba diametrs var būt 300mm, 500mm, 600mm.

Mēs varam griezt dažādus garumus atkarībā no klienta prasībām.

Augstas ātruma oga piegādes un griešanas mašīna līnijā

Plāksņu atvilkšanas līnija savienojas ar izlādes pārvadi, un spiedējs var automātiski pārvietot žurnālus uz žurnālu ielādētājiem no korku atvilkšanas vai plāksņu atvilkšanas mašīnām.

|

Modelis

|

BHJ1615

|

|

Maks. darba diametrs

|

300mm-1500mm

|

|

Maksimālais darba garums

|

6000mm-pielāgoti

|

|

Sīpolu tips

|

Aplis vai ķe Edwards tips

|

|

Motora jauda

|

38kw

|

|

Noklusējuma spriegums

|

380V

|

Galvenie funkcijas

Žurnālu krustlīdzājs, stažu žurnālu ielādētājs, žurnālu garās ielādes, apļveida šķēres, žurnālu garās izlādes.

Divi veidi šķēršu izvēlei: apļveida šķēres vai virpžogu tips.

Mūsu žurnālu sagriešanas līnija plaši tiek izmantota planku ražošanā, lai sadalītu garus žurnālus dažādos garumos, piemēram, 4 pēdas, 8 pēdas vai citos.

Hanvy Machinery ATVILKŠANAS LĪNija

Tas aizņem vietu 38x8m.

Pilna līnija ietver:

1. Koka bilžu piegādes aparāts 2. Koka bilžu atsvaidzinātājs 3. Atsvaidzināto koka bilžu piegādes aparāts 4. Dēvju dēvēšanas mašīna

5. Veneeras pārvades 6. CNC veneeras rotācijas griezējs 7. Veneeras sastādītājs 8. Atlikuļu pārvades josta

Hanvy Machinery SPIEDUMA LĪNija

karstas spiļģu mašīna, 10/15/20 slāņi, atvērums 70mm vai pielāgoti.

SIEMENS PLC kontrole, 5 dažādas spiediena kontroles, 6 režīmi dati augstas skiedru kvalitātei.

CE sertifikācija, īpaši augsta kvalitāte Kinijā. Noklikšķiniet uz attēla, lai iegūtu detalizētu saiti.

Hanvy Machinery PLYWOOD MACHINERY-Par mūs

Turcija, Krievija, Polija, Vācija, Brazīlija, Ukraina, Meksika, Austrālija, Austrumu Āzija, Afrikas, ASV utt.

1 gada garantija visām mašīnām, instalācijas un starta pakalpojumi tiek sniegti mūsu profesionālajā inženieru komandā.

|

Pakošana

|

||

|

Izmērs

|

20ft

|

|

|

Svars

|

7600kg

|

|

|

Iepakojuma detaļas

|

Saistas filmas kopumā, mazie rezerves daļiņas ir pakārti pliķu kastēs

Zemāk ar plīte palētu forklifta transportam.

|

|

Hanvy Machinery

Ar lepnumu piedāvā savu jaunāko koka šķērēšanas mašīnu: Fantomas Lumber Chain Saw Cutting Machine Sawing Line Log Cut Off Saw. Runājot par koka, fantomas vai koka šķērēšanu, Hanvy Machinery šķērēšanas līnija ir ideālais rīks. Mūsu šķērēšanas līnija ir dizainēta, ņemot vērā klienta vajadzības un prasības.

Šī funkcija darbojas ar hidraulisku sistēmu, kas padara to ļoti vieglu pārvaldīt un kontrolēt. Mašīna ir aprīkota ar pārvades sistēmu, kas pārvieto meža būtiņus uz automātisko šķērsošanas procesu, kas nodrošina efektīvus un precīzus griezumus. Hanvy Machinery Mašīnas griešanas process ir vienkāršots un palīdz sasniegt optimālus rezultātus, izmantojot šo ierīci.

Vidū no izcilo funkciju ir tā augstā ražības tempa. Tā ir izveidota, lai pārvaldītu lielu apjomu, galvenokārt vienkārši. Tā var ātri sadalīt līdz 1200-1500 būtiņu stundā, kas nozīmē, ka darbs tiek paveikts ātri un bez problēmām.

Ilgstoigs un drosmīgs. Tas var izturēt smagu klimatu un lielas slodzes. Izgatavots no augstas kvalitātes materiāliem, šī ierīce nodrošina ilgu dienestspēju un drošību. Šī īpašība nozīmē, ka lietotājiem nav jābaidās, ka mašīna sabojās vai strādā nepareizi, nodrošinot uzticamu un ilgtspējīgu izmantošanu.

Lietotāja draudzīgs. Tās kontroļas izmantošana ir intuitīva, un sistēmas lietotāji var viegli operēt ar iekārtu. Iekārtas vienkāršais dizains nodrošina, ka pirmreizējie lietotāji var sākt to izmantot bez jebkādiem grūtiem momentiem. Pieejams ar lietotāja rokasgrāmatu, kas skaidri parāda ierīces funkcionalitāti un uzturēšanas instrukcijas.

Iegādājieties šo Hanvy Machinery Machinery Plywood Lumber Chain Saw Cutting Machine Sawing Line Log Cut Off Saw, lai pieredzētu efektīvu un precīzu koka griešanas procesu.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ