Produkta pielietojums

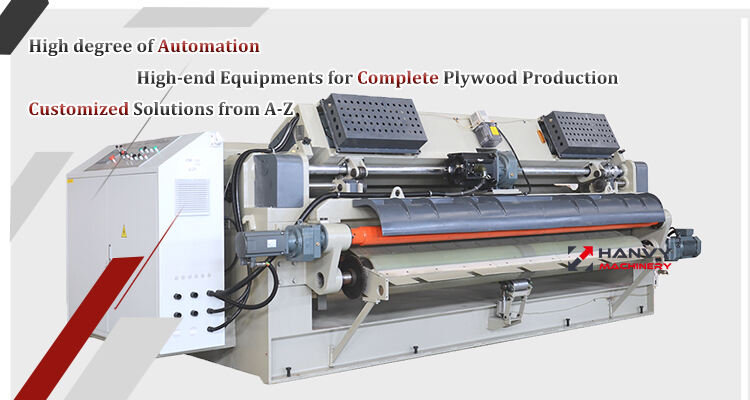

Japānas sistēmas koka veneeras mašīna Veneera izmazgāšanas ražošanas līnija

Hanvy Mašīnbūves uzņēmums ir oriģinālais un profesionālais pliķu ražošanas mašīnu ražotājs, mēs varam jums piedāvāt pilnu veneeras laidšanas līniju pliķu ražošanai.

Šī dēvju līnija bez spindles ir ļoti populāra visā pasaulē dēvju un peldošo skābju nozarē.

Tas aizņem vietu 38x8m.

Japānas sistēmas koka veneeras mašīna Veneera izmazgāšanas ražošanas līnija

Pilna līnija ietver:

1. Koka bilžu piegādes aparāts 2. Koka bilžu atsvaidzinātājs 3. Atsvaidzināto koka bilžu piegādes aparāts 4. Dēvju dēvēšanas mašīna

5. Veneeras pārvades 6. CNC veneeras rotācijas griezējs 7. Veneeras sastādītājs 8. Atlikuļu pārvades josta

|

Modelis

|

HXQ2700

|

HXQ2000

|

HXQ1500

|

|

Darba diametrs

|

Φ500 mm

|

Φ500 mm

|

Φ500 mm

|

|

Maksimālā darba garums

|

2600 mm

|

2000 mm

|

1350 mm

|

|

Šķērslu biezums

|

0.5-3.0 mm

|

0.5-3.0 mm

|

0.5-3.0 mm

|

|

Koka sirds diametrs

|

Φ 40 mm

|

Φ 40 mm

|

Φ 40 mm

|

|

Vēlera izvades ātrums

|

30-100 m/min

|

30-100 m/min

|

30-100 m/min

|

|

Kopējā motora jauda

|

52 KW

|

40 kW

|

28,1 kW

|

|

Kopējā dimensija

|

5200x2500x1850 mm

|

4500x2500x1850 mm

|

3800x2200x1850 mm

|

|

Svars

|

13500 kg

|

12000 kg

|

9000 kg

|

Produkcijas līnija skābju veidnei

Solis 1: Koka bumbuņas nošķēršana

Koka piegāde + koka bumbuņu nošķēršana

Šī mašīna izmanto rotācijas griešanas principu, kas tiek veicināts ar hidraulisko spiedienu, un ātri noņem bumbuņas, veicot koka aploksni.

koka diametrs 140-500mm

koka garums 1400-2600mm

Lieliem koka diametriem un garumiem mēs varam pielāgot citu veidu koka bumbuņu nošķēršanai.

Plywood plāksnju atvilkšanas līnija

Solis 2: CNC bez vamzda rotācijas šķiešanas mašīna

Tas var atvilkt koku ar diametru no 40mm līdz 500mm, uzlabojot koka izmantošanu.

Līžņu materiāls: augstas aliejuma okaļstals

Maks. darba garums 2600mm/2000mm/1350mm

Parkošanas izvades ātrums 30-100m/min

Pneimātiskais spiediena bīle

CNC bīļa vārti

Līnijas riņķa ceļš bumbieru šraubs

Ķermeņa laminācijas šķiešanas ražošanas līnija

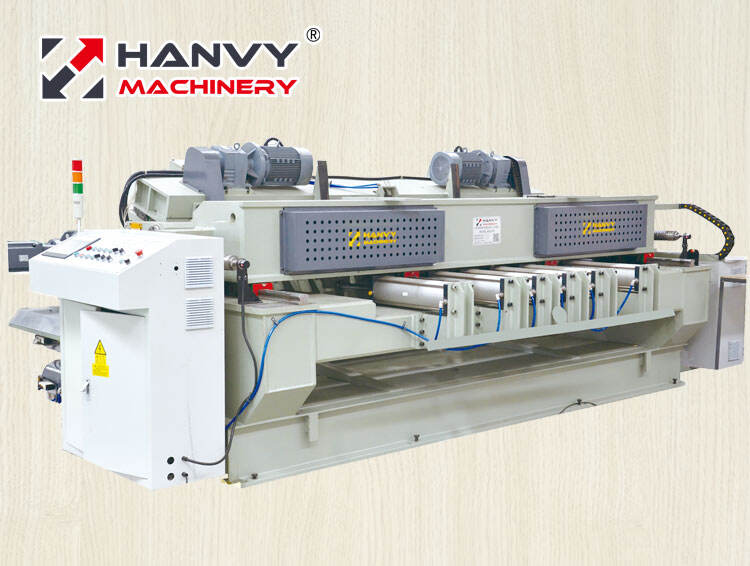

Solis 3: CNC parkošanas rotācijas šķēres

Komplektēts ar izvades konvejoru, servomotora sistēmu, parkošanas izvades ātrums 100m/min.

Japānas Yaskawa sistēma/Siemens sistēma

Maks. darba platums 2650mm/2000mm/1450mm

Griešanas diametrs 2700mm/2150mm/1500mm

Rullis diametrs 398mm

Hanvy bez vamzda laminācijas šķiešanas līnija

Solis 4: Automātisks vēlnes sasvaidzinātājs

Šis vakuumtips automātiskais vēlnes sasvaidzināšanas aparāts uzlabo ražošanas efektivitāti un samazina ražošanas izmaksas.

Sasvaidzināšanas izmēri 8ftx4ft vai 4ftx8ft

Maks. darbības platums 2600mm/1350mm

Vēlne mērciņu biezums 1.0-3.0mm

Maks. ātrums 140m/min

Maks. sasvaidzināšanas augstums 1000mm

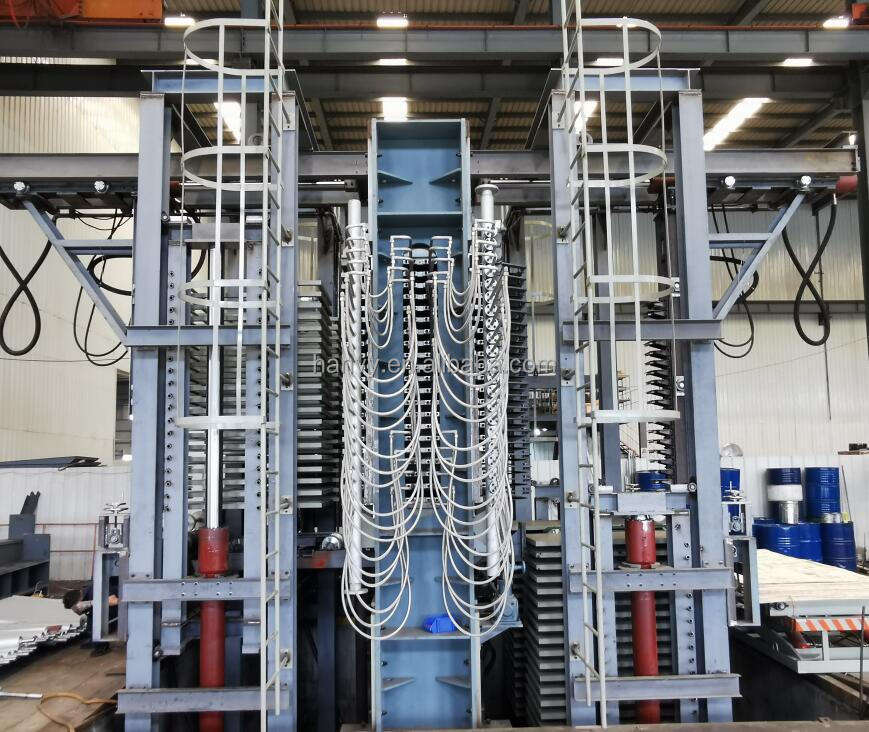

HANVY SPIEDĒŠANAS LĪNija

Spiešanas līnija ietver 500Tonņu aukstspiešanas mašīnu ar automātisko ievadi un izvadi, SIEMENS PLC kontroles sistēmu.

600Ton vai 800Ton karstspiešanas mašīna, 10/15/20 slāņi, atvērums 70mm vai pielāgoti.

SIEMENS PLC kontrole, 5 dažādas spiediena kontroles, 6 režīmi dati augstas skiedru kvalitātei.

CE sertifikācija, augstākais kvalitātes līmenis Kinijā. Nospied augstāk minētā attēla detalizētais saite.

HANVY PLOKŠTĀM MAŠĪNAS

Mēs esam uzkrājuši vairāk nekā 30 gadu pieredzi un veiksmīgi ietekmējam starptautiskos tirgus. Mūsu pilnīgais assortiments sastāv no mašīnām, piemēram, koku bultu atbārdisanas aparātiem, skiedra gabala lāpstošanas mašīnai, skiedra šķietuvām, lipītavas izplatītājiem, kolonām planku ražošanai, karstajiem spiekiem, planku D.D. segļiem, mājniecības koka apstrādes iekārtām un koka / bultu šķēdēm un formētājiem.

Hanvy pliķu mašīnas līdz šim tiek aktīvi pārdotas vairāk nekā 60 valstīs, piemēram, Turcijā, Krievijā, Polijā, Vācijā, Brazīlijā, Ukrainā, Meksikā, Austrālijā, Austrumu Āzijā, Afrikā, ASV utt.

1 gada garantija visām mašīnām, instalācijas un starta pakalpojumi tiek sniegti mūsu profesionālajā inženieru komandā.

|

Pakošana

|

|

|

|

40HQ

|

|

|

|

9800kg

|

|

|

|

Saistas filmas kopumā, mazie rezerves daļiņas ir pakārti pliķu kastēs Zemāk ar plīte palētu forklifta transportam.

|

|

Ķīnas pilna pletņas skārde ražošanas līnija

Vēnēmācīna šūpošanas mašīna

Līdzekļu izplatīšanas mašīna

Piedāvājiet Japānas sistēmas koka laminācijas mašīnu izgatavošanas mašīnu šķiešanas ražošanas līniju caur Hanvy iekārtām - spēle maina pakalpojumus koka tirgū.

piedāvā augsttehnoloģiju sistēmu koka bultu šķiešanai, kas rezultātā ir efektīvi un precīzi veic koka laminācijas ražošanu. Izmaiņas inovācijas izmantošana ne tikai uzlabo efektivitāti, bet arī samazina darba devu, mazina zudumu un izmaksas.

Sniedz drošu un ilgtspējīgu servisu. Tas tiešām ir apvienots ar uzlabotiem senzoriem, kas noteicina koka bultu izmēru un formu un pielāgojas atbilstoši, lai griezuma laukums būtu optimāls. Tas nozīmē, ka katru koka bultu notver precīzi, samazinot atkritumus un veicinot vairāk videi draudzīgu ražošanas procesu.

Var tikt viegli pārvaldīts jebkuram, neatkarīgi no viņu prasmes līmeņa kokaindustrijā. Lietotāja saskarnes ir viegli lietojamās, un vienkārši sekojamas instrukcijas padara ražošanas līniju vieglu pārvaldīt.

Turklāt ietver augstas kvalitātes zaru, kas precīzi šķie koka bultas, radot mīkstu un tīru virsmu, kas ideāla augstas kvalitātes koka plāksnēm. Zars izgatavots no drošiem materiāliem, nodrošinot tā ilgtspēju un nepieciešamību reti aizvietot.

Vēl viens brīnišķīgs iekļautais elements ir tā spēja ražināt parketdēļu plāksnēm dažādās biežumos. Tas ietver ražošanas procesa elastību, ļaujot izveidot pielāgotas parketdēļu plāksnes, lai apmierinātu tirgus dažādās vajadzības.

Japan System Wood Veneer Machine Making Machine Peeling Production Line no Hanvy Equipment ir uzticams un efektīvs ražošanas risinājums meža industrijai, sniedzot augstas kvalitātes parketdēļu plāksnes, samazinot darba izmaksas un zudumu. Lietojot uzlabotu tehnoloģiju, tiek nodrošināts, ka katrs loks tiek atņemts precīzi, kas rezultē ar tīru un gudro virsmu, samazinot zudumus. Šis ražošanas līnija ir ilgtspējīgs risinājums ražotājiem, kas meklē ekoloģisku un ekonomisku alternatīvu tradicionālajām meža ražošanas metodei.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ