Produkta pielietojums

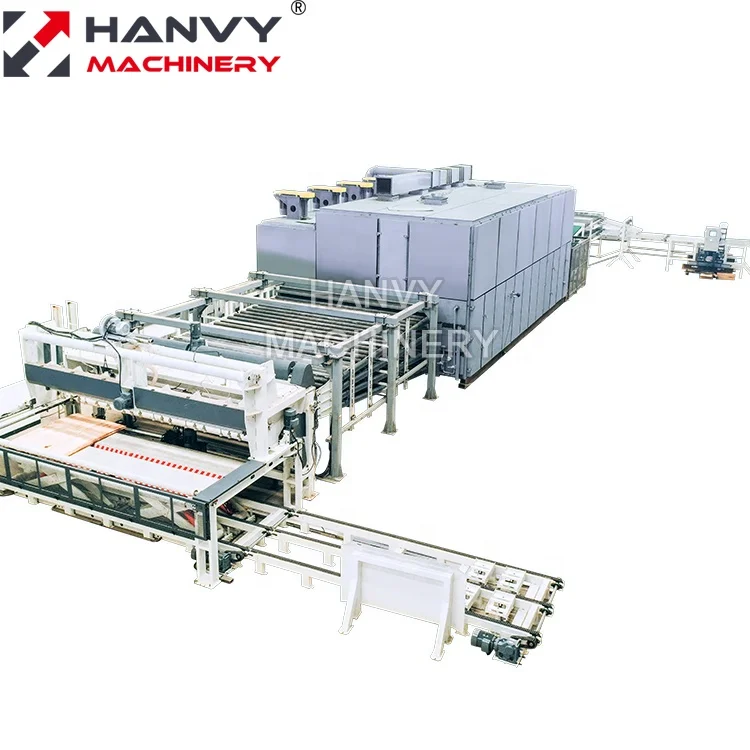

Automātisks 4 līmeņu nepārtraukts vēlmašīnas šķēles sausinātājs, izmantojams kārtona ražošanai

Šī mašīna ir galvenā mašīna kartonu ražošanai, tā tiek izmantota attīrītiem cietokšņiem sausināšanai.

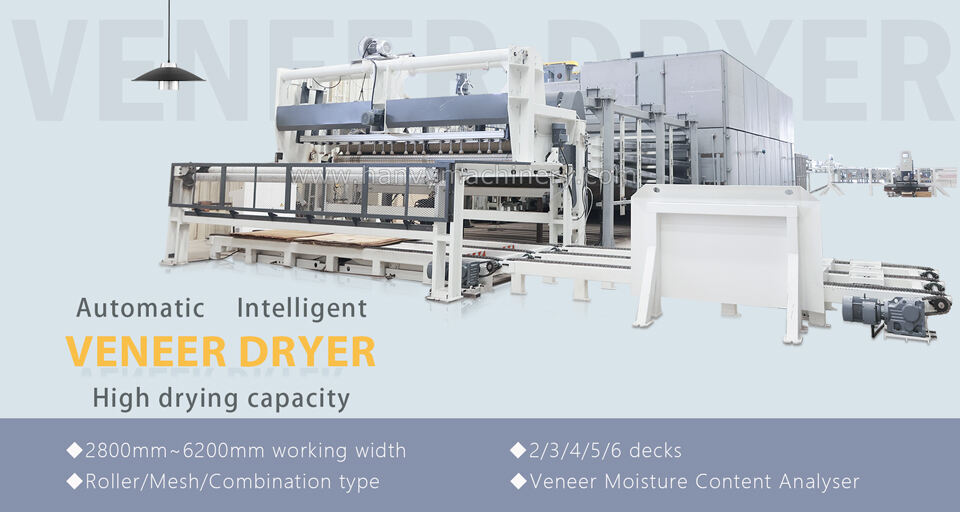

Tas ietver tīklu, valku un tīkla & valka tipu, to var pielāgot saskaņā ar jūsu prasībām.

Tas darbojas ar augstu efektivitāti, taupot enerģiju un uzlabojot cietokšņa kvalitāti.

Valku / tīkla tips Šķēpu sausīšanas mašīna plīvura ražošanai

Automātisks 4 līmeņu nepārtraukts vēlmašīnas šķēles sausinātājs, izmantojams kārtona ražošanai

|

Modelis

|

HDR2-8

|

HDN3-10

|

HDN1R2-13

|

|

Šķērslu biezums

|

1,5 mm

|

0.6 mm

|

Neto 0.6 mm

Valks 1.5 mm |

|

Viltums

|

80%

|

80%

|

80%

|

|

Darba platums

|

2800 mm

|

2650 mm

|

Tīkls 2650 mm

Rullis 2800 mm |

|

Starpkoka skaits

|

2

|

3

|

3

|

|

Sildīšanas daļa

|

2000×8 mm

|

2000×10 = 200000

|

2000×13 = 260000

|

|

Dzesēšanas daļa

|

2000×1 mm

|

2000×1 mm

|

2000×1 mm

|

|

Pārvades ātrums

|

1.5 ~ 15 m/min

|

3 ~ 36 m/min

|

Tīmeklis 3 ~ 32 m/min

Rullis 1.5 ~ 15 m/min |

|

Sāusēšanas spēja

|

2.1 m³/h

|

4.5 m³/h

|

Tīmeklis 1.9 m³/h

Rullis 3.7 m³/h |

|

Tvaika patēriņš

|

1800 kg/h

|

2600 kg/h

|

3580 kg/h

|

|

Kopējais motoru

|

77.2 kw

|

139.5 kw

|

172.5 kw

|

|

Izmērs

|

23307×4080×2884 mm

|

27675×5200×4400 mm

|

33680×5200×4210 mm

|

|

Svars

|

34500 kg

|

71500 kg

|

92000 kg

|

Galvenie funkcijas

1. Šķēpu biežums 1,5 mm, piemērots skaistmateriāla šķēpu sausīšanai valkājam sausītājam plāksnēm.

2. Šķēpu biežums 0,6 mm, piemērots skaistmateriāla šķēpu tīkla sausīšanai plāksnēm.

3. Astoņas (8) siltumistabas, katrai sērijai 2 m;

4. Viens (1) dzesēšanas istabas 2 m.

5. Viltuma līmenis 80%;

Hanvy Mašīnu sertifikāts

Mums ir ISO un CE sertifikāti daudzām plokštīnu mašīnām, kas atbilst Eiropas Savienības un ASV kvalitātes standartiem.

Hanvy Mašīnas - Par mums

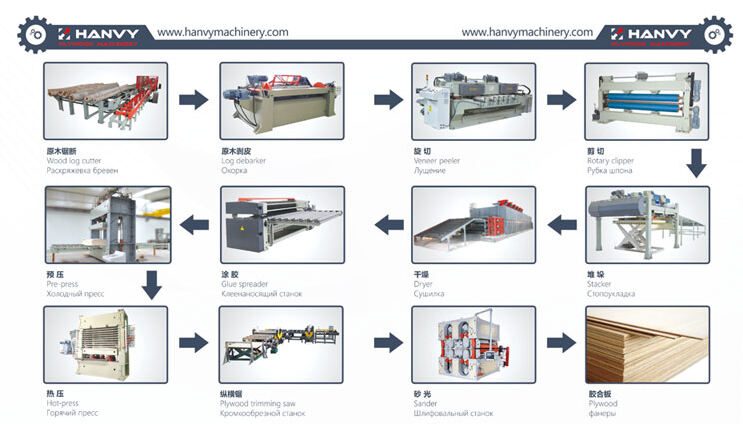

Mēs esam uzkrājuši vairāk nekā 30 gadu pieredzi un veiksmīgi ietekmējam starptautiskos tirgus. Mūsu pilnīgais assortiments sastāv no mašīnām, piemēram, koku bultu atbārdisanas aparātiem, skiedra gabala lāpstošanas mašīnai, skiedra šķietuvām, lipītavas izplatītājiem, kolonām planku ražošanai, karstajiem spiekiem, planku D.D. segļiem, mājniecības koka apstrādes iekārtām un koka / bultu šķēdēm un formētājiem.

Hanvy pliķu mašīnas līdz šim tiek aktīvi pārdotas vairāk nekā 60 valstīs, piemēram, Turcijā, Krievijā, Polijā, Vācijā, Brazīlijā, Ukrainā, Meksikā, Austrālijā, Austrumu Āzijā, Afrikā, ASV utt.

1 gada garantija visām mašīnām, instalācijas un starta pakalpojumi tiek sniegti mūsu profesionālajā inženieru komandā.

Hanvy Mašīnbūve

Automātisks 4 plāku nepārtrauktais valkājamais parketes šķietmašīnas ir ideālais risinājums parketes ražotājiem, kas vēlas palielināt savu ražošanas efektivitāti, saglabājot augstākās kvalitātes produktus. Šī modernā mašīna ir dizainēta, lai automātiski sausinātu un izlīdzinātu parketes lapas, gatavojot tās turpmākai apstrādei.

Tas var apmierināt lielu parketes lapu daudzumu vienā ciklā ar četriem šķietšķiedriem. Hanvy Mašīnbūve Vijoliņš konstanti nodrošina, ka parketiermateriāla lapas tiek apstrādātas ar iekārtu efektīvi, neuzsūdzot tos vai nesabojājot. Lietojot šo iekārtu, varat gaidīt līdz 40% ātrākas sausināšanas laikus, pateicoties uzlabotam gaisa plūsmas sistēmai, kas nodrošina karstumu.

Augsttemperatūras kontroles sistēma nodrošina precīzu un konstantu siltumu visā sausināšanas procesā, samazinot iespēju, ka parketiermateriāla lapas sprāgst vai sadalās. Iebūvētā mitruma mērīšanas sistēma palīdz uzturēt precīzu mitruma līmeni sausināšanas laikā, nodrošinot vienmērīgu biežumā un drošību parketiermateriāla lapām.

Iekārtas uzlabotais sausināšanas tehnoloģija atbilst dažādiem koka veidiem un biežumiem, kas to padara elastīgu dažādu ražošanas prasībām. Tā ilgtspējīgā konstrukcija nodrošina, ka tā var izturēt smagus plywood iekārtu ražošanas apstākļus, sniedzot uzticamu servisu ilgstoši.

Kompakts un viegli pārvaldāms, kas to padara ideālu mazām un plywood izstrādāšanai, kurā lielas ziedu. Remonts prasa minimālus ieguldījumus, un mašīna ietver pilnas lietotāja rokasgrāmatas un tehniskā palīdzība no Hanvy Machinery komandas.

Sazinieties jau šodien, lai uzzinātu vairāk par šo Hanvy Machinery Automātisko 4 stāvu nepārtraukto velosipēda tīras šķēpu sushanas mašīnu un kā tā var palīdzēt jūsu plywood ražošanas uzņēmumiem.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ