Do you ever wonder how plywood is created? Plywood is actually unique type of wood that serves various purposes creating some types of things like furniture and along with rebuilding since it can be utilized to build houses, make glass etc. It is a composite of many thin layer woods combined to create strong and long lasting material. Once upon a time, the production of plywood required great effort and manpower. However, nowadays we have a special machine that simplifies and speeds up this process. One such machine is the plywood making machine and it revolutionized the methods of creating a ply from solid wood.

The plywood making plant is an automated machine that helps to manufacture the plywood in short time. It is intended to process an uncut wood into very thin layers of it all by itself with little human intervention. The machine now glues those individual layers of wood together, become a larger sheet in size to what the client need. This machine works really quickly, so this makes a lot of plywood in very little time. This speed is highly beneficial as it enables companies to quicker produce plywood and satisfy builders and furniture makers.

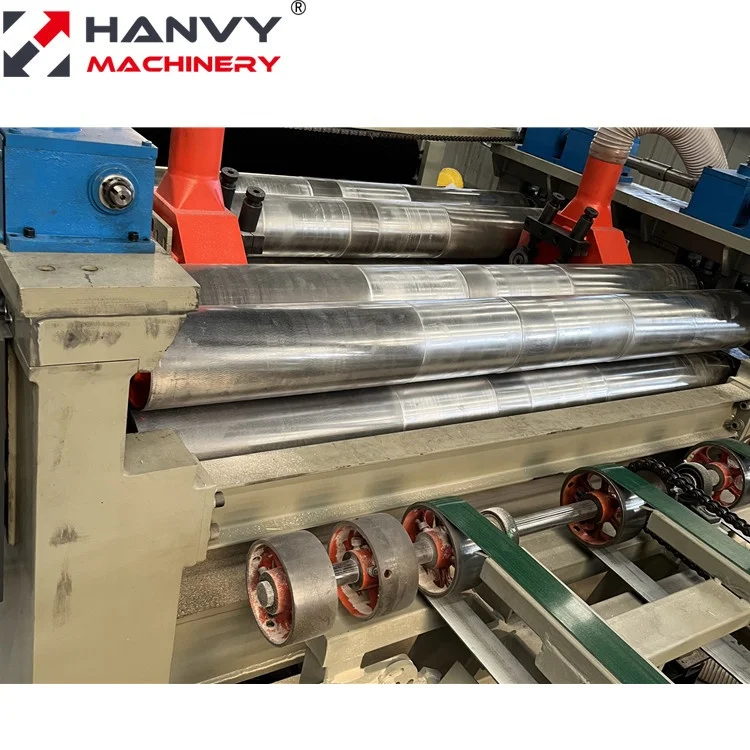

The inside of the plywood making machine is made using new technology and modern methodology which helps to produce higher grade quality of a strong built up reliable Plywood. With that simple construction in mind, the saw mill is as user friendly to operate as words can describe: practically anyone who has an interest of making plywood can learn how to run it with relative ease. This machine operates on different parts just like a cutting device to cut the wood, gluing equipment for layering and drying method so that each element turns set. They all have a value in the creation of the best plywood's possible.

The machine is capable of making sterile and robust sheets. This material makes use of glue that is quite strong to attach each layer and hold them in place, hence why it is added. Since this adhesive is quite strong, that means the plywood will have a long lifespan and can be employed in several applications. Besides that, the machine also makes a lot of sense for smoothing and levelling on surface materials like plywood. The smooth finish is huge because it makes the plywood usable for really nice furniture and other projects that we want people to use.

There is no such better equipment than the plywood making machine to convert wood into flat sheets of plywood. This has a new species of wood that can easily become different types of plywood_restart, giving you many options to create. It is operable as well in producing plywood of different dimensions and thickness which signifies its flexibility. You can use this ply to do almost any project - furniture making, house building or just simply making your own plywood for hobby purposes. This guy is just the best for whatever you need it to do.