Description:

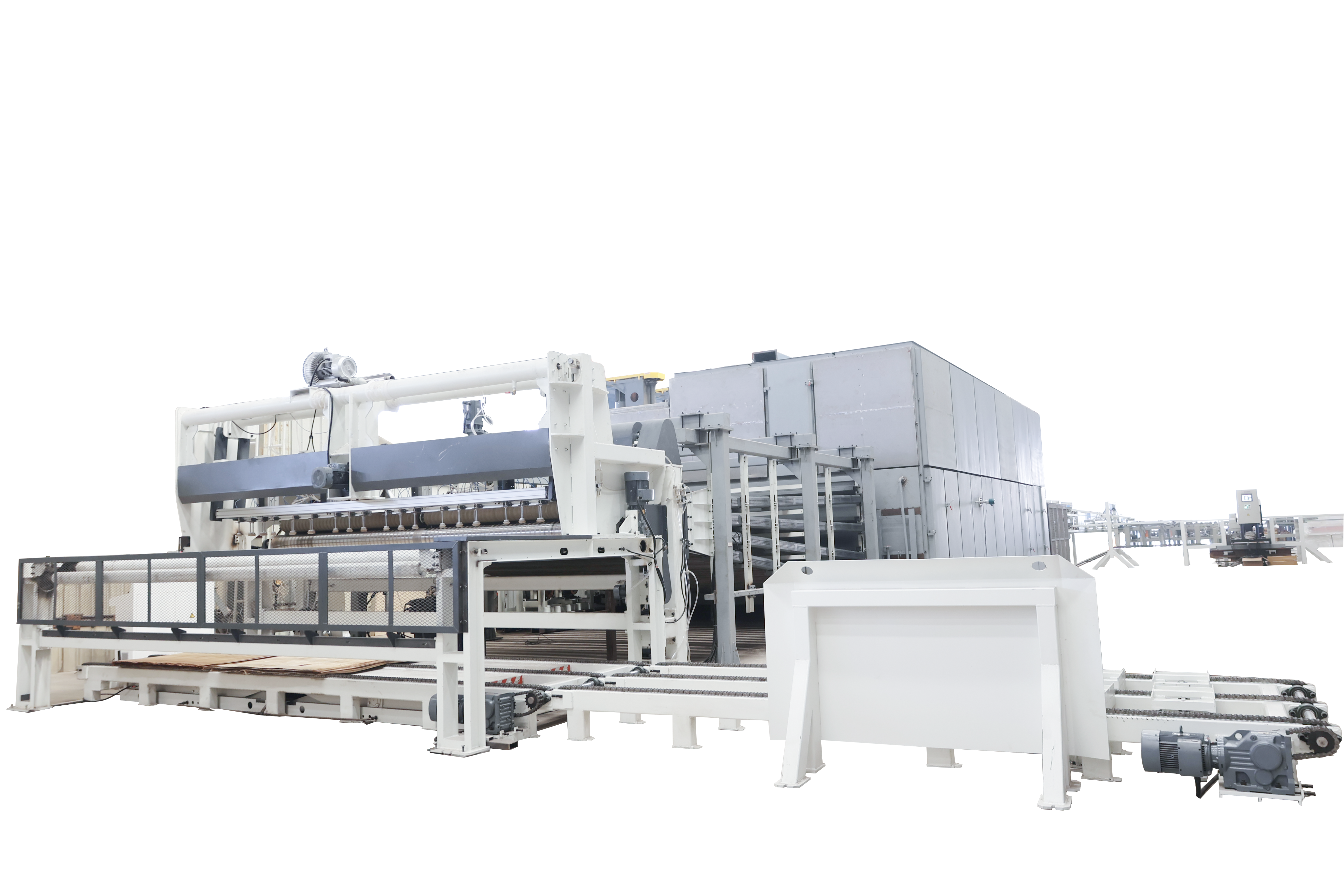

Veneer drying is one of the key stages in veneer production. The main goal of the drying process is to produce high quality dried veneer with the highest possible efficiency. This is achieved by using hot and humid air inside the dryer to remove moisture from the veneer and reduce the moisture content to an optimum level.

We can provide a variety of different series of veneer drying lines according to the customer's choice, and can classify the dried veneer into different veneer types by matching with moisture analyzers, quality analyzers and other equipments. It's available for plywood or LVL production.

Main Features:

*Uniform moisture content of veneer after drying

*Unique jet box structure, which can effectively avoid veneer blocking

*Efficient centrifugal fan and heat sink for high veneer output

*Efficient insulation measures effectively reduce energy consumption

*All fans are on the same side for easy maintenance

*Labor saving, the whole production line only needs 1 to 2 employees to operate

*Infeed overlap system (optional), which can increase production capacity by up to 10%

*Temperature and air humidity control system (optional), automatically adjusts the temperature and humidity in the drying room, saving up to 20% energy consumption per cubic meter of veneer produced

*Automatic fire extinguishing system (optional)

Specifications:

| Model | HG132/3000-8+1 | HG182/3000-8+1 | HG192/3000-8+1 | HG133/3000-8+1 | HG183/3000-8+1 | HG193/3000A-8+1 | HG193/3000B-8+1 | HG134/3000-8+1 | HG184/3000-8+1 | HG194/3000-8+1 | HG134/5000-6+1 | HG134/5900-6+1 | HG134/6300-6+1 | |

| Type | - | 2 Rollers | 2 Meshes | Mesh&Roller | 3 Rollers | 3 Meshes | 1 Mesh&2 Rollers | 2 Mesh&1 Rollers | 4 Rollers | 4 Meshes | 2 Meshes&2 Rollers | Wide 4 rollers | Wide 4 rollers | Wide 4 rollers |

| Working width | mm | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 5000 | 5900 | 6300 |

| Deck number | - | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 |

| Heating section length | mm | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 12100 | 12100 | 12100 |

| Cooling section length | mm | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 |

| Drying capacity | m³/h | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 6.5 | 7.5 | 8.5 |

| Steam consumption | kg/h | 1780 | 1780 | 1780 | 2580 | 2580 | 2580 | 2580 | 3380 | 3380 | 3380 | 5040 | 5460 | 6000 |

| Total motor | kw | 81.2 | 85.5 | 80.7 | 116.7 | 120.7 | 116.7 | 120.7 | 141.2 | 160.2 | 156.2 | 146.2 | 257.2 | 257.2 |

| Transmission motor | kw | 11+2.2=13.2 | 7.5*2+2.2=17.5 | 11+7.5+2.2=20.7 | 11+7.5+2.2=20.7 | 7.5*3+2.2=24.7 | 7.5+11+2.2=20.7 | 7.5*3+2.2=24.7 | 11*2+2.2=13.2 | 7.5*4+2.2=32.2 | 7.5*2+11+2.2=28.2 | 11*2+2.2=24.2 | 11*2+2.2=24.2 | 11*2+2.2=24.2 |

| Heating motor | kw | 7.5*8 | 7.5*8 | 7.5*8 | 11*8 | 11*8 | 11*8 | 11*8 | 15*8 | 15*8 | 15*8 | 18.5*6 | 37*6 | 37*6 |

| Cooling motor | kw | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4.2 | 4*2 | 4*2 | 5.5*2 | 15*2 | 15*2 |

| Transmission speed | m/min | 0-15 | 0-25 | 0-25/0-15 | 0-15 | 0-25 | 0-25/0-15 | 0-25/0-15 | 0-15 | 0-25 | 0-25/0-15 | 0-15 | 0-15 | 0-15 |

| Overall dimension | mm | 29100*5260*3680 | 29600*5260*3700 | 38195*5260*3730 | 29100*5260*4180 | 32600*5260*4900 | 38195*5260*4230 | 38195*5260*4430 | 29100*5260*4680 | 32600*5260*5170 | 38195*5260*4930 | 25100*7060*4800 | 25100*8160*4800 | 25100*8560*4800 |

| Weight | kg | 45000 | 42000 | 43500 | 49000 | 46000 | 47500 | 47000 | 56000 | 52000 | 59000 | 75000 | 89000 | 95000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ