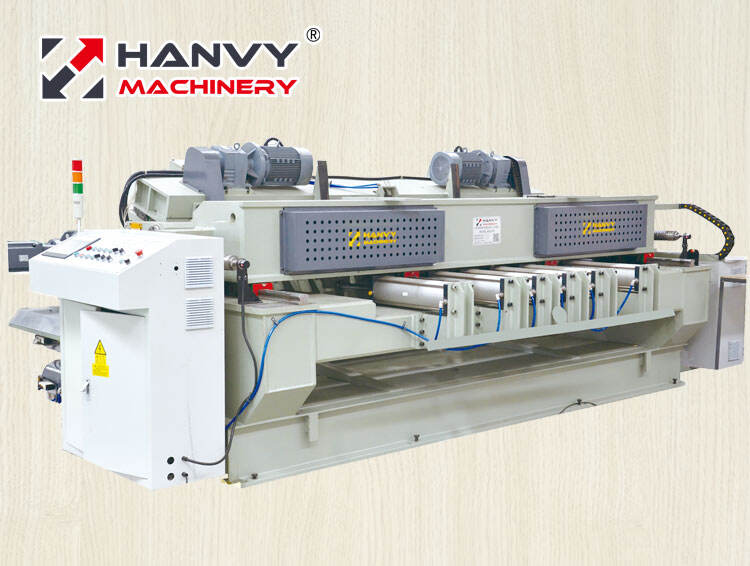

الخطوة 1: جهاز نزع قشرة الشجر

تغذية الشجر+Nزع قشرة الشجر

تستخدم هذه الآلة مبدأ القطع الدوراني لآلة التسوية الدوارة بدون كتل، وتُدار بضغط هيدروليكي، مما يمكنها من إزالة القشرة بسرعة وتجعل تسوية السجل.

قطر السجل 140-500 مم

طول السجل 1400-2600 مم

لأقطار السجلات الكبيرة وأطوال السجلات، يمكننا تخصيص نوع آخر من آلة إزالة قشر السجلات.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ