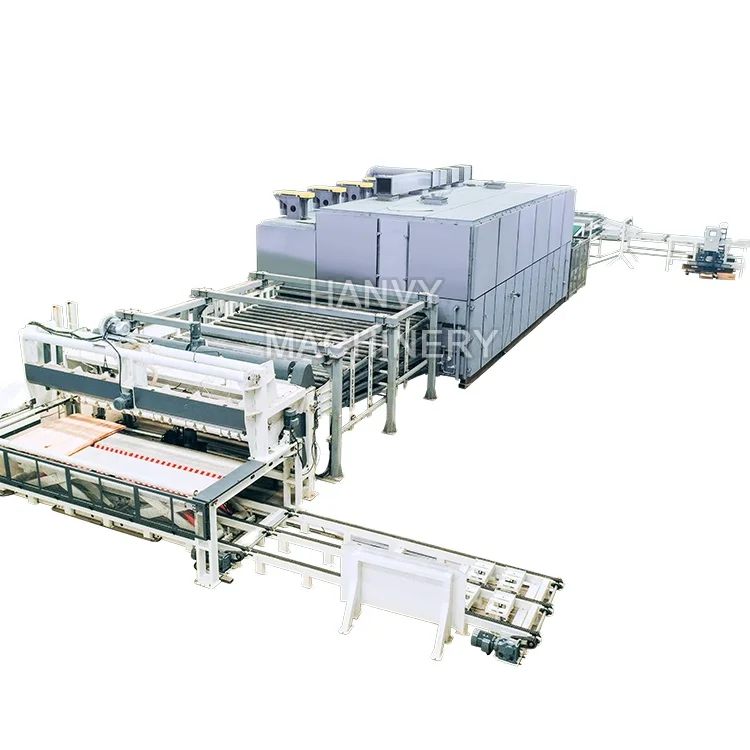

Veneer Dryer Machine — This type of dryer machine for veneers is made ready to dry the wood in vein-cut. It works by blowing hot air in contact with the wood. The heat will kill any moisture present in the wood veneers. It is the water concentration that could render wood too wet to be useful with respect to its strength. During the production of veneer sheets for furniture and flooring, it is important that these be dried plane on this dryer.

Drying the wood veneers Cautions & Precision throughout Its job is to keep the temperature and humidity at a level that will get us proper veneer drying. That's why it called as Veneer dryer machine? It means that it regulates the temperature, humidity and equipment air which makes them leave at room speed of breathing in nwhich must be accomplished with proper plastics so they dont get ruined when dry.

But it is that since dry weight has been possible to develop a specific control system which allows you always know what level of humidity and temperature are in the chamber where dried. The wood drying chamber — an enclosed space, in which there is a system that regularly checks those conditions to keep the levels at their adequate range while monitoring if all of them are safe for wood veneers. So, you should be vigilant because if your goal to get the most strong and durable wood then vigilance is must.

A veneer dryer machine is not an ordinary equipment, it has come with intelligent technology features thereby they are dust proof while working the most efficient. The fan on this machine is quite robust and that is one of the main highlights about it. This is the fan blowing hot air even hotter on wood veneers. This makes the wood dry fast and completely (so that it is perfect): because through this, hot air will flow throughout the plane which gives a good uniformity in drying.

However, the veneer dryer machine has heating system too. This prevents the drying chamber temperature from changing while wood is flowing through it. Nicely as retaining the wood veneers from both twisting or even great parting, and Information is important for you to always keeping an actual heat. It is also possible to finish the drying too quickly or unevenly, but this machine partly helps address these issues.

The apparatus itself module hit fuelling electrodes, the (automatic) dryer gift verify sensors. All it takes is a few of these sensors to determine when the wood veneers you're laying are either too wet or dry. The chamber will detect a certain level of moisture and keep the moisture to a specified humidity at different temperatures. So it is able to adjust the circumstances so that the wood veneers are dried accurately. It makes it more productive and automates the saving of time.

In this way using veneer dryer machine may improve the quality of venner sheets produced. This assures to able the timber is desiccated optimally as a best answer of, for preparing it durable and available with stuffs like furniture that can be put together & flooring. Splendorsheet, BigIf your veneer sheets did not thump the nail in head right there then something is familiar going no.