Certainly the wood is a material more special, and it serves to shape countless things. Plywood (Holding One): There comes a very essential thing which is manufactured in wood and that's Plywood. Plywood is made by laminating sheets of very thin wooden layers on top of each other and then applying extensive pressure. After doing so, you will get a nice and sturdy sheet of wood that can be useful for many things (even to build furniture or some types of buildings).

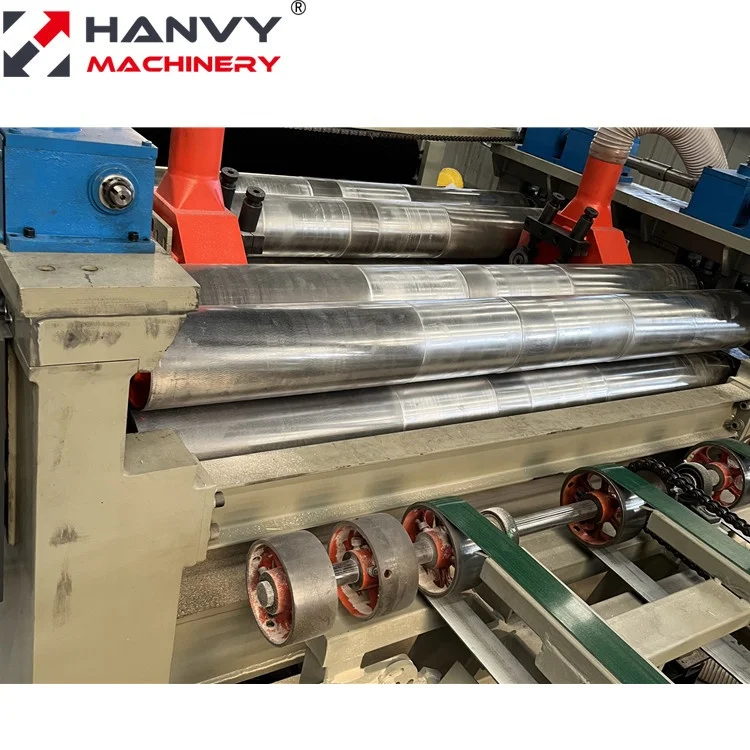

A hot press machine is used to press the wood layers with each other. Operating on the principle of heating big metal plates and then pressing them in to wooden layers. The heat from the plates and pressure caused by the machine allow all layers of wood to stick together strongly, creating an uniform piecematerial. The hot press machine does not only bond the wood layers, but it can also shape any size and form of plywood as needed.

The hot press machine is vital as it speeds up the production of making plywood. Instead of workers manually stacking wood layers and pressing it together by hand the machine does all this. This saves a great deal of time and energy! This allows the machine to produce multiple sheets of plywood all at once, making it perfect for companies using massive quantities of wood each day.

The hot press machines also feature some of the latest technology to produce plywood with high strength and quality. The plates in the machine become very hot, allowing to thermo-bond the layers of wood effectively. Furthermore, the machine adjusts its pressure according to how deep it needs to press onto the wood for all particles of said provide needed and maximum equal surface pressed evenly right. This is what imakes plywoods so strong and dependable.

A hot press machine is crucial for the easy and efficient production of plywood. The machine does all of that a lot more efficiently than either having workers do it by hand. It gives the opportunity to produce more quantity in a short time, means increasing ply wood. A perferct solution for companies who are under pressure to produce a vast number of ready made plywood products as fast and cheaply as possible

The hot press machinery which is used for the purpose of preparing plywood significantly increase its strength and endurance. Such high temperatures and pressures from the machine causes it to form a strong bond of wood layers. The end result is more durable ply that is less likely to snap or buckle, and so can be used with confidence in a variety of applications.

The hot press machine completely revolutionized the process of how plywood is made today. This powerhouse puts the layers of wood together without requiring just a mass number of workers to mash it all down into its final and agreed upon shape. The best part about it is - saves time, effort and money as well! The machine also has an important function in the manufacturing process, which is that it can produce many sheets of plywood at once.