Hello everyone! Subjectodox … and today we learn about the cool cold press machine for plywood. Do you not know how is the plywood made? Plywood - plywood is a type of engineered wood produced by gluing together thin sheets of veneer. All of these layers are laminated together to create a stiff and robust sheet. The cold press machine is so important for the good plywood because it actually stacks or combines these layers in a stacked manner that they stick together perfectly. That is, and how does it work..?

Cold Press machines are among the many advantages to producing plywood. The first aspect of these handy tools is to flatten and sand the plywood into a smooth surface. This implies that there are no roof-like roughness or waves on the wood! The layers of wood are compressed tightly under pressure using a cold press machine to avoid any gaps or high places. The layers will bond better with the glue when pressed down tightly, which makes a strong and reliable output.

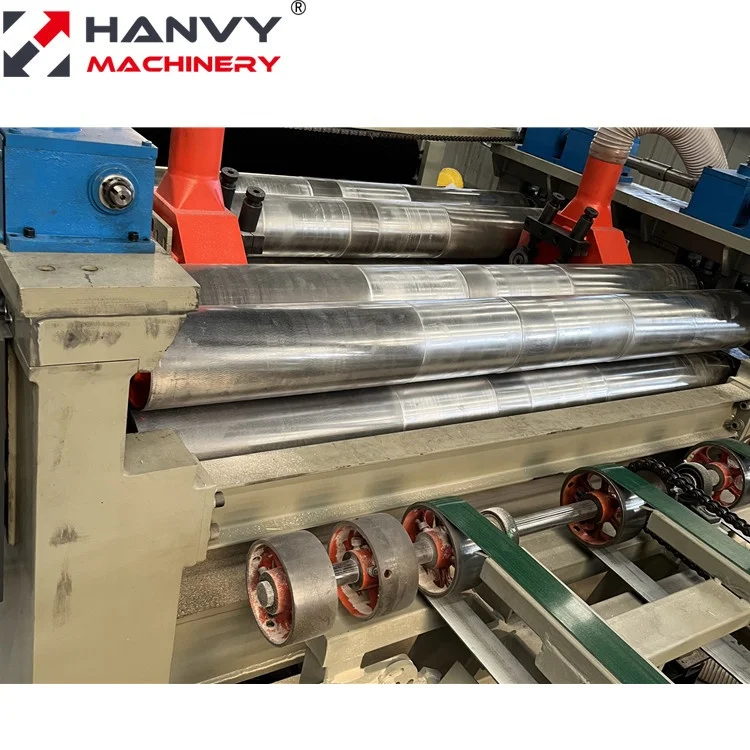

The machine utilized is a simple but clever cold press that has an important role in the process of making the plywoods. It consists of two main sections known as plates. It's formed by a top plate, which can move up and down, next to another bottom stationary at one end of the components. The device puts the layers of wood veneers between those 2 plates and then forces them together by the upper plate getting pushed down.] This method of squeezing ensures strong adherence between wood layers. This pressure required is then applied by hydraulic cylinders that can push the top plate down onto layers of wood. This is what makes the plywood tough and robust.

Natural gas is used in Firestone's Cold Press technology, which allows it to bond rubber compounds securely but with no need for a hot press -- this results not only save times but also conserve natural resources(ident1).

The use of cold press machine plywood production has achieved high quality, and it can save materials as well. The machine creates high pressure - which requires a small quantity of glue and less layers or wood to make strong plywood. That is good news because it means there will be less material lost in the job. Add to that, less material of course means better for the environment as a whole in life cycle production achieved by such methods. A cold press machine empowers manufacturers to be responsible and efficient at the same time.

One of the best methods for producing robust and higher quality plywood products is Cold pressing. The pressure is created by the machine compressing together all layers of wood tightly, which allows for a very strong finished product. Once you feel the end result, the finished plywood is smooth to touch, and it looks beautiful easy on the eye. This is something that builders and craftsman love because it results in a more beautiful, high quality project.

So, you may want to know what is the best way for making plywood: cold pressing or else? This depends on what you are trying to do. Therefore, a cold press will work best for high quality and sturdy plywood that may last you forever! But if you need a quicker and cost-effective way of manufacturing your plywood, there are several possible alternatives. All those methods have advantages and disadvantages, so in the end it depends whether you prefer quality or money.