An automatic hot press machine is a powerful and efficient device that applies heat as well as pressure to many layers of wood for the production of plywood. This works through pressing the layers together and heating, like a gum. This is why it is referred to as automation becouse you can perform all the tasks by itself, no human assistance needed. This gives you it the rate faster and Does not More must be worked manually unlike an older machines.

By using an automatic hot press machine, the operation is simplified and can get the production done faster. This particular machine can help businesses produce more plywood in less time. Even better, the machine is extremely accurate and so it can generate high-quality plywood that will meet every standard for durably and strength.

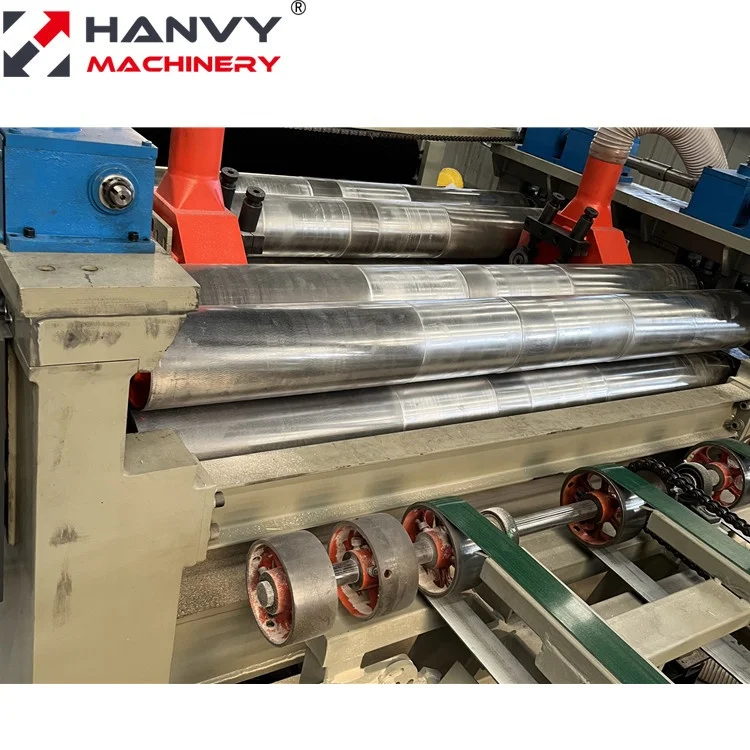

Automatic Hot Press Machine for Making Thick and Thin Plywood2-in-1 HOT PRESS MACHINEThis continuous roller type hot press machine with capability of both thick(15~45 mm) and thin (3, 6 or 9mm). In fact, it can create plywood with faces of different types and complete several levels of finishing so that manufacturers are equipped to make the finest products ever.

Automatic Hot Press to Save Money and Make Plywood Easily! Plywood is lower-grade material, but with a shorter man-hours as well it should be considerably less expensive to manufacture. It produces less waste because the machine itself generates fewer scraps which is beneficial for our planet and economical as well.

Nearly above the machine work and also they can not rest for a longamination. This makes multiple plywood prints happen at a lightning speed, guaranteeing that manufacturers can keep up with customer orders without waitingroduced Ungapped Block Palettes Fast Production Process Printingsemble Syndromecycle who knows how long. This finds particular applicability in the fast-paced efficiency driven world of a competitive market.

In the using process of hot press machine researchingUniversity/38, make sure we also pay attention to its maintenance. So take care of your coffee maker, and it will run perfectly for years to come. If the unit is not well regulated, it could slowly and gradually begin to fail and following that this results in a manufacturing challenges.

Good quality internal wood layers are very important as well. The better the wood species you use, more beautiful and solid your plywood. It is a work with woods tool So you have to choose the best wood according to its need. That way the final product does what a customer needs it to do.