Quick Detail:

Log debarker,log peeling machine, log debarking machine

Description:

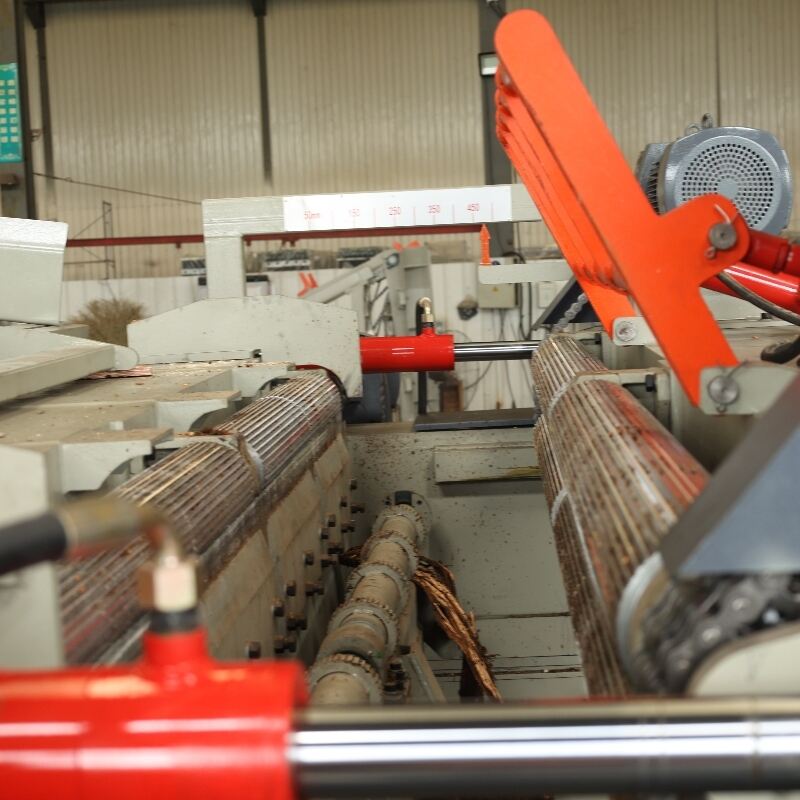

The core of the log debarker is that it utilizes the principle of rotating peeling, which is different from the traditional chuck-based rotary lathes. Log debarkers use this spindleless rotary lathe method, eliminating the need to clamp the wood during the debarking process. Instead, it uses rollers to support the log, ensuring a smooth, even peeling experience while minimizing the risk of surface damage.

The key to the log debarker's outstanding performance lies in the adaptability of its drive mechanism. The equipment offers motor drive for the G Series and hydraulic drive for the Y Series, providing users with unparalleled flexibility in selecting the propulsion system that best suits their operational requirements. Whether you are looking for the precision of electric motor-driven operation or the robustness of hydraulic power, log debarkers provide optimal performance based on individual needs.

A hydraulic log centering device integrated into the log debarker further increases operating precision. This innovative feature ensures precise alignment of logs during debarking, minimizing deviations and maximizing efficiency. By maintaining consistent positioning, it facilitates seamless bark removal, resulting in superior output quality and reduced material waste.

The pneumatic log receiving unit complements the hydraulic log centering unit and is designed to simplify the loading process through fast and efficient log reception. This component is designed to integrate seamlessly into workflows, minimizing downtime and maximizing productivity. Its pneumatic operation ensures smooth and reliable performance even in demanding production environments.

For operators looking for enhanced functionality, the log debarker offers an optional shredder. This feature provides the ability to efficiently dispose of debarked wood residue, reducing waste and supporting eco-friendly disposal practices. By incorporating a shredder into their workflow, operators can optimize resource utilization and minimize environmental impact, in line with sustainable manufacturing principles.

All in all, the log debarker is a testament to innovation and excellence in wood processing equipment. Using the rotary debarking principle, diverse drive options, precision-focused design features and optional shredder function, it represents a leap forward in bark removal technology. Whether used in a sawmill, lumber yard or wood processing facility, log debarkers enable operators to achieve unparalleled levels of productivity, efficiency and quality in their operations.

Specifications:

Traditional Log Debarker

| Model | HBP1550G | HBP1850G | HBP2250G | HBP2750G | HBP3350G |

| Working diameter | φ150-φ500 mm | φ150-φ500 mm | φ150-φ500 mm | φ150-φ500 mm | φ150-φ500 mm |

| Working length | 1500 mm | 1800 | 2200 mm | 2600 mm | 3300mm |

| Rotary peeling speed | 47 m/min | 47 m/min | 47 m/min | 47 m/min | 47 m/min |

| Total motor power | 24 kw | 31.5kw | 35.5 kw | 35.5 kw | 49.5kw |

| Overall dimension | 3650*2370*1730 mm | 3950*2370*1730 mm | 4810*2370*1730 mm | 5490*2370*1730 mm | 5790*2370*1730 mm |

| Weight | 5900 kg | 6500kg | 7200 kg | 8000 kg | 9000kg |

Hydraulic Log Debarker

| Model | HBP1560Y | HBP1860Y | HBP2260Y | HBP2760Y | HBP3360Y |

| Working diameter | φ150-φ600 mm | φ150-φ600 mm | φ150-φ600 mm | φ150-φ600 mm | φ150-φ600 |

| Working length | 1500 mm | 1800 | 2200 mm | 2600 mm | 3300mm |

| Rotary peeling speed | 50 m/min | 50 m/min | 50 m/min | 50 m/min | 50 m/min |

| Total motor power | 27.5(22+5.5) kw | 35.5(15+15+5.5) kw | 42.5(18.5+18.5+5.5) kw | 42.5(18.5+18.5+5.5) kw | 49.5(22+22+5.5) |

| Overall dimension | 3060*3000*1800 mm | 3380*3000*1801 mm | 3780*3000*1802 mm | 4180*3000*1803 mm | 4960*3000*1804 |

| Weight | 6850 kg | 7550 kg | 8200 kg | 8800 kg | 10100 kg |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ